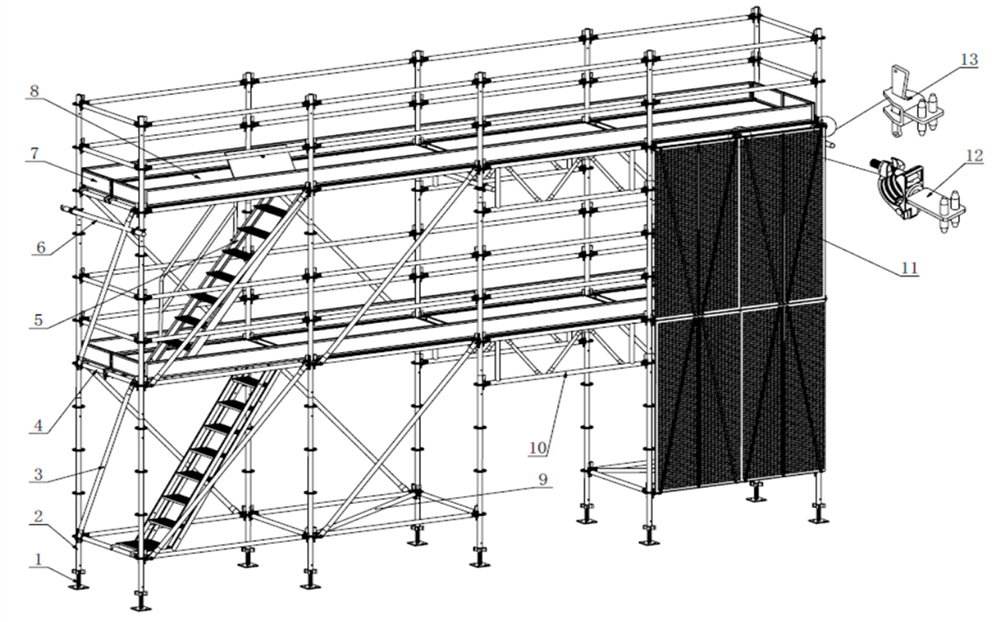

Ring Lock Aluminum Scaffold

Aluminum Ringlock System– Main component

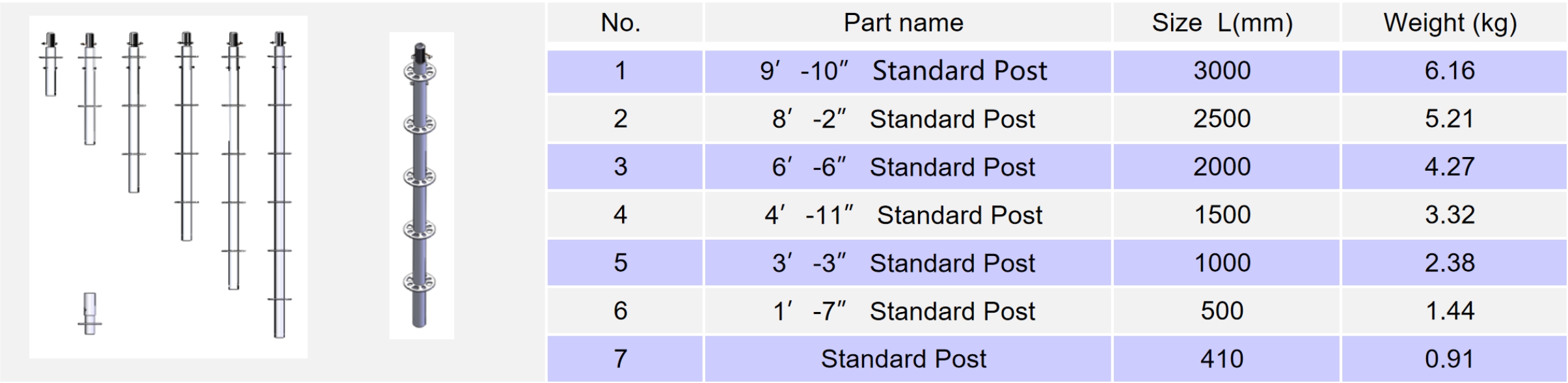

Standard Post (Φ48.3X4 6061-T6)

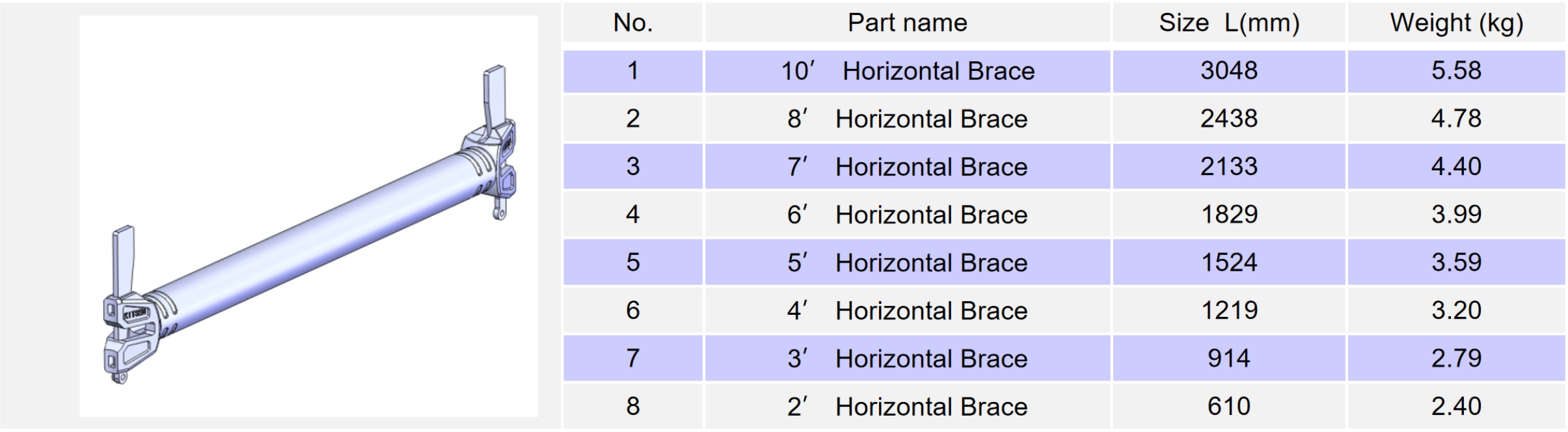

Horizontal Brace (Φ48.3X2.5 6061-T6)

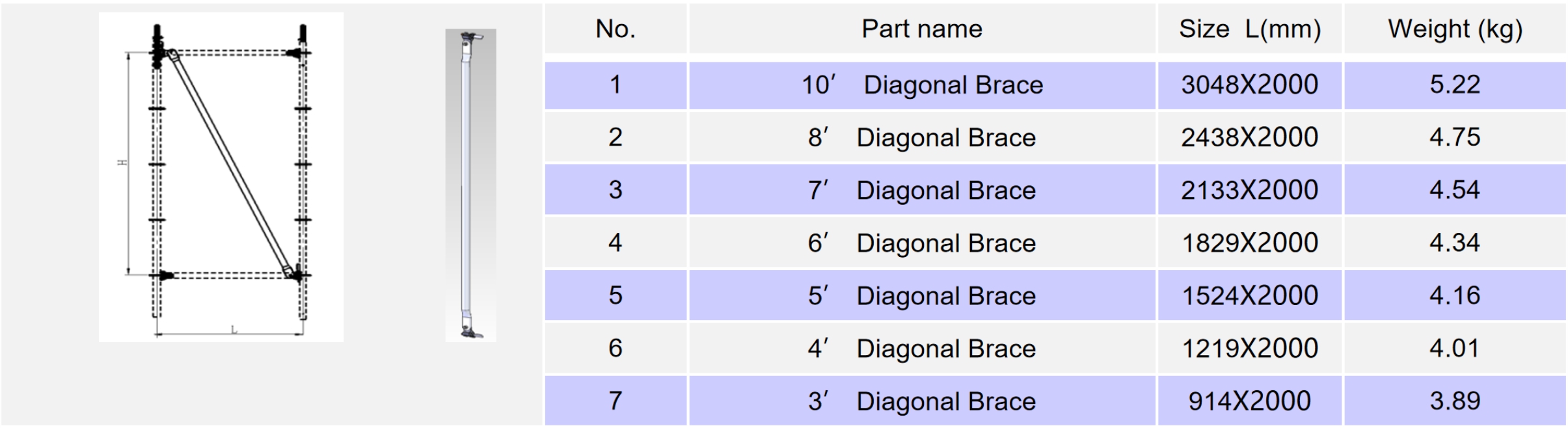

Diagonal Brace( Φ48.3X2.5 6061-T6)

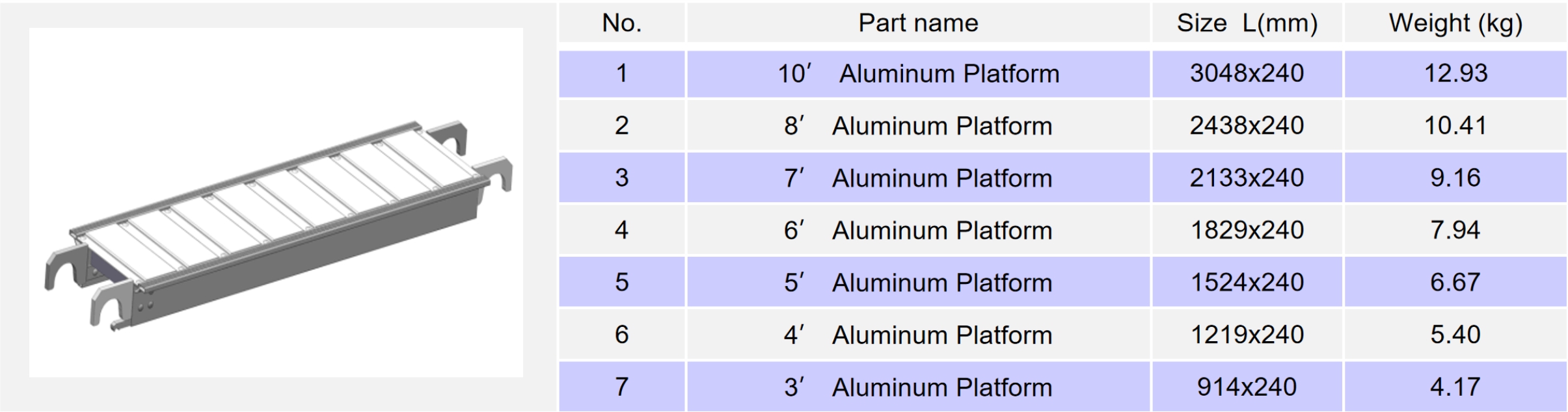

Aluminum Platform(2mm 1060-H24)

|

Ring Lock Aluminum scaffold is a modular structure, which is composed of a set of interconnected prefabricated aluminum alloy scaffolding.

|

Notes:

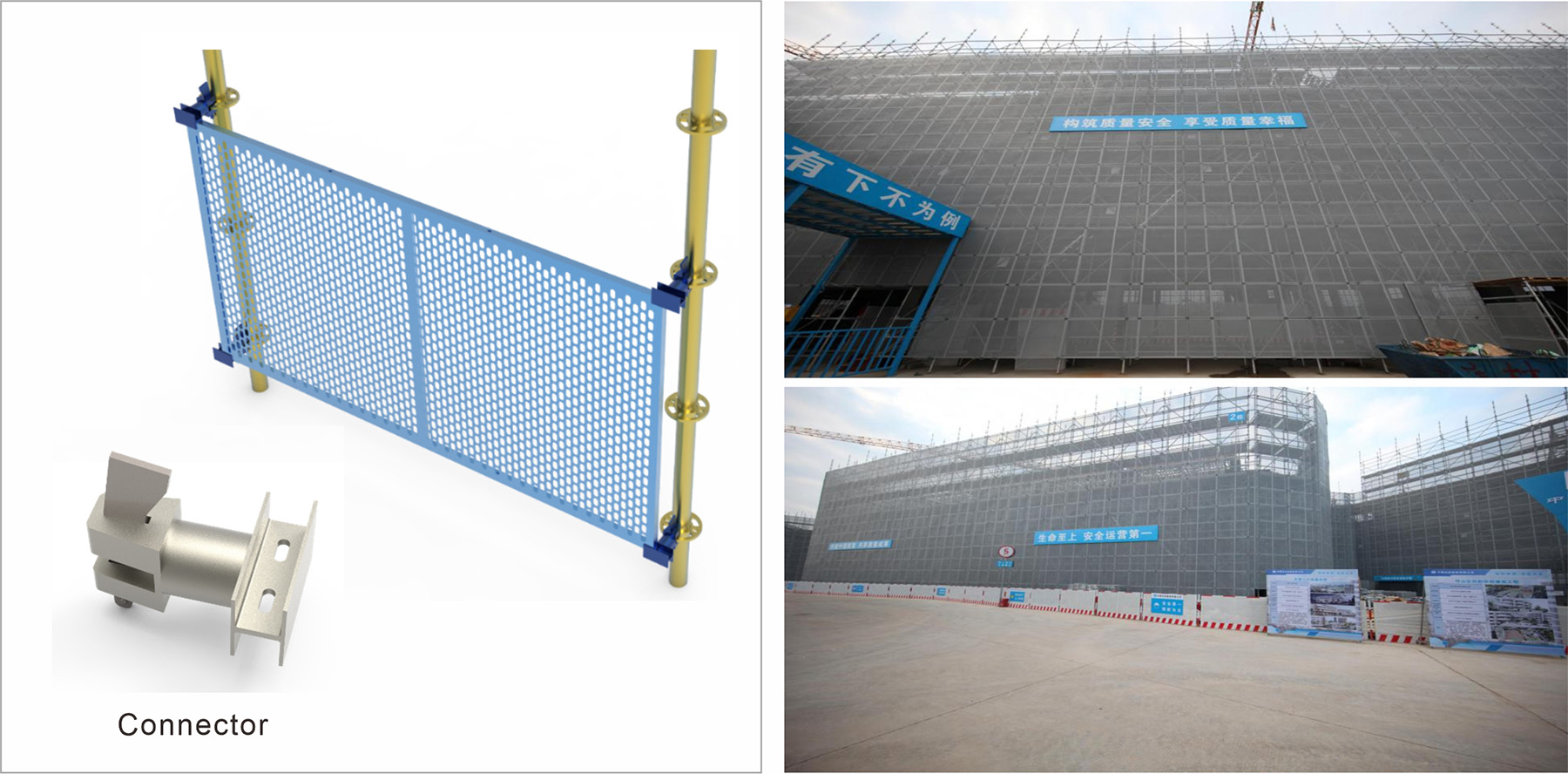

1. Adjustable Base 2.Standard Post 3.Diagonal Brace 4.Horizontal Brace 5.Landing ladder 6. wall fastener 7. Skirting Board 8. Aluminium Platform 9. Horizontal inclined bar 10. Horizontal Truss 11.Grid Guard 12. The Horizontal rod Connector of Grid guard 13. The Vertical Rod Connector of Grid Guard |

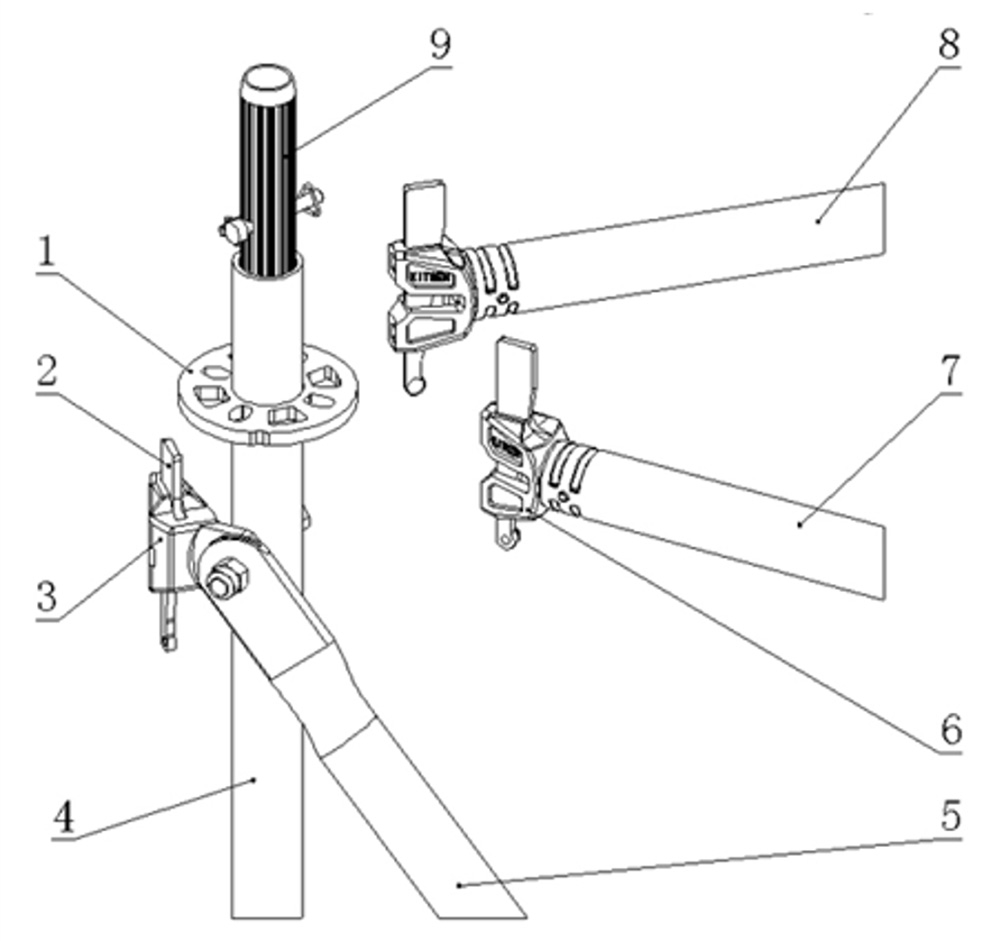

The Node Construction Diagram of Disc Pin Al-alloy Scaffold

|

Notes:

1. Connecting Disc 2. Fastening Pin 3.The Buckle joint of inclinde post 4. Standard post 5. Vertical Diagonal Bar 6. The Buckle Joint of Horizontal Brace 7. Horizontal Brace 8 Horizontal Diagonal Brace 9. Conncecting Sleeve |

The Function of Each Component

|

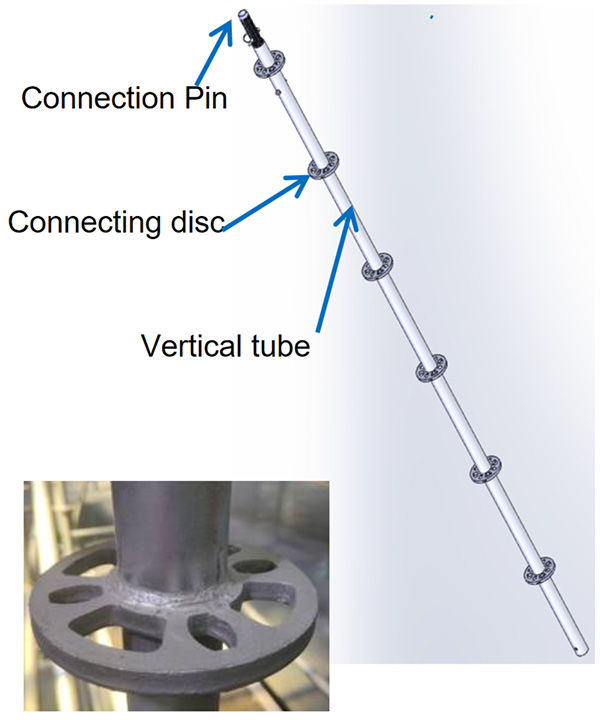

1.Standard Post

① The material of the tube body is 6061-T6 or 6082; ② The tube body is set up every 500MM welding 8-hole connecting disc; The axes of each member are at one point. The main force of the frame is axial compression. Because of the connection of the inclined tie rod, each unit of the frame is similar to the lattice column, so the bearing capacity is high and it is not easy to destabilize. ③ The connecting pin is fixed at one end of the vertical rod and is used for the vertical rod to vertically extend the inner cannula |

|

|

Standard Post LG

L=500、1000、1500、2000、2500、3000 |

|

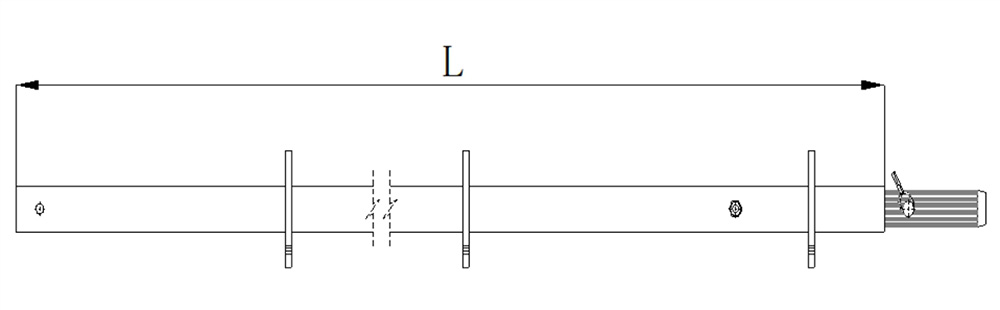

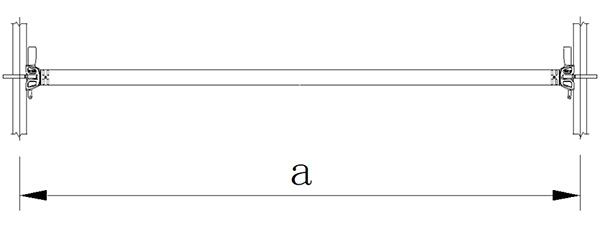

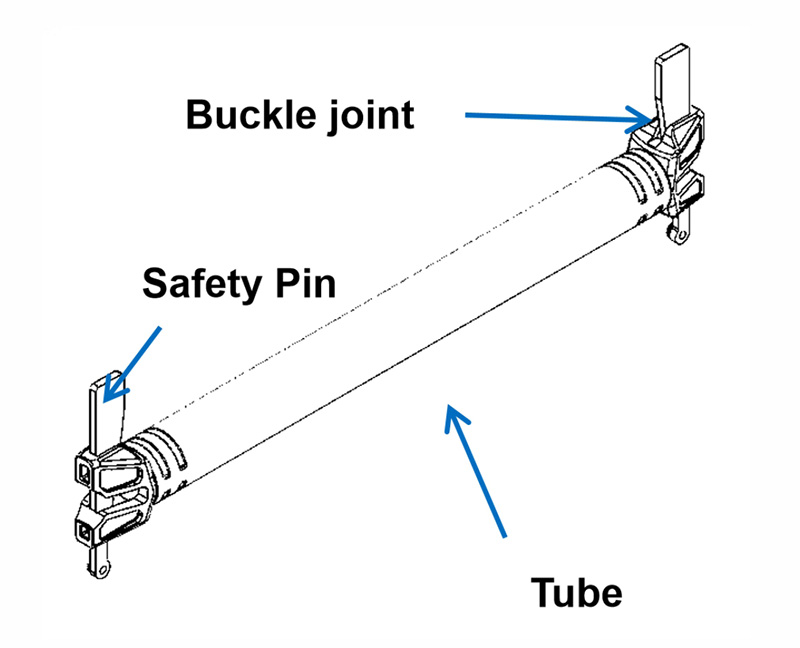

2. Horizontal Brace

① The tube material is 6061-T6 or 6082. ② Both ends of the riveted casting buckle joint and the disc of standard post are connected by the safety pin of horizontal brace.

|

|

Horizontal brace SG

a=300、600、900、1200、1500、1800、2100、2400、2700、3000

a=300、600、900、1200、1500、1800、2100、2400、2700、3000

|

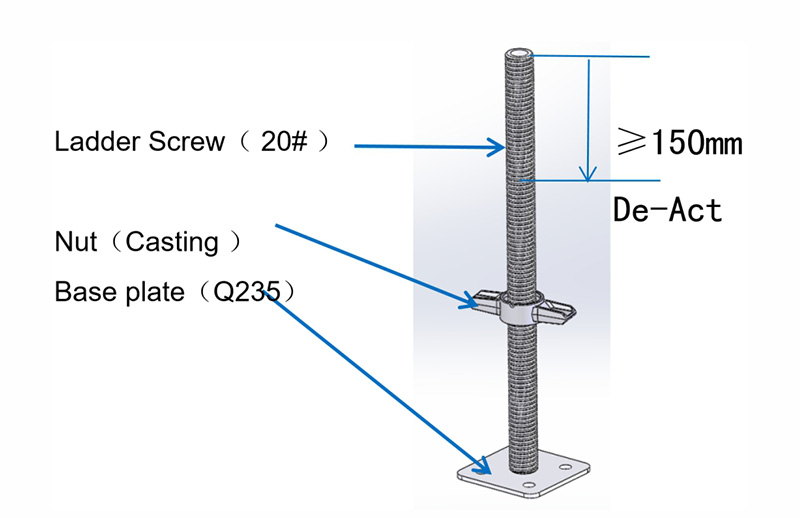

4. Adjustable base

Insert the base with the adjustable height of the vertical rod. It is mainlu used to adjust the frame in an uneven environment. |

|

|

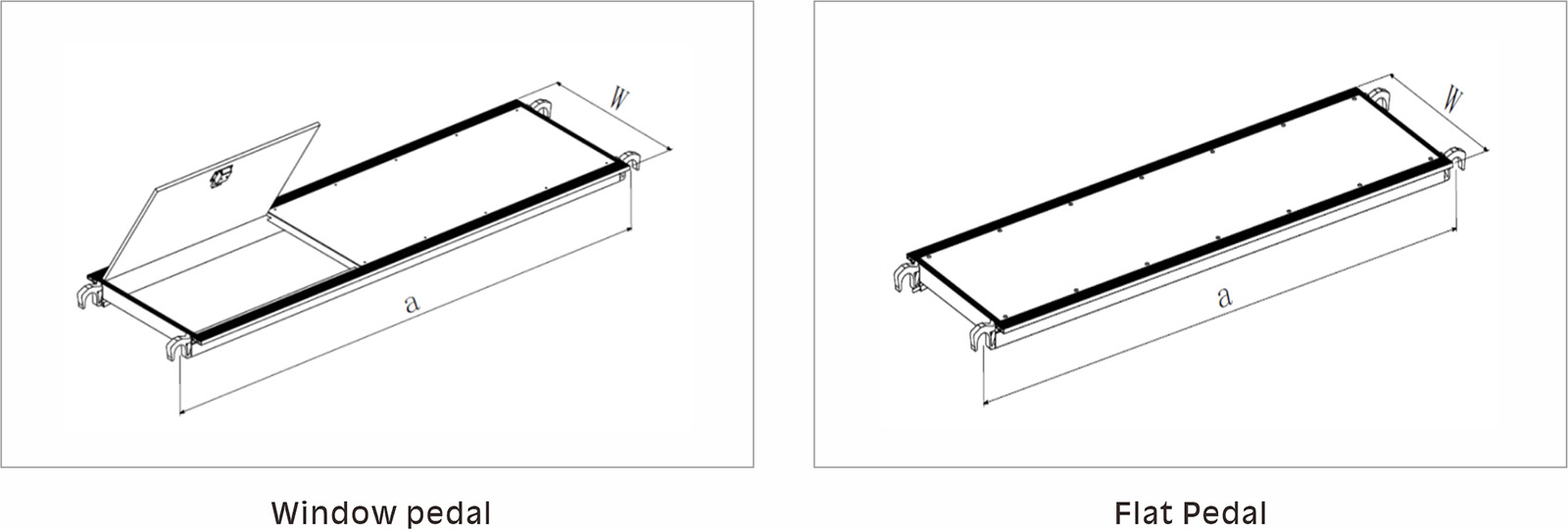

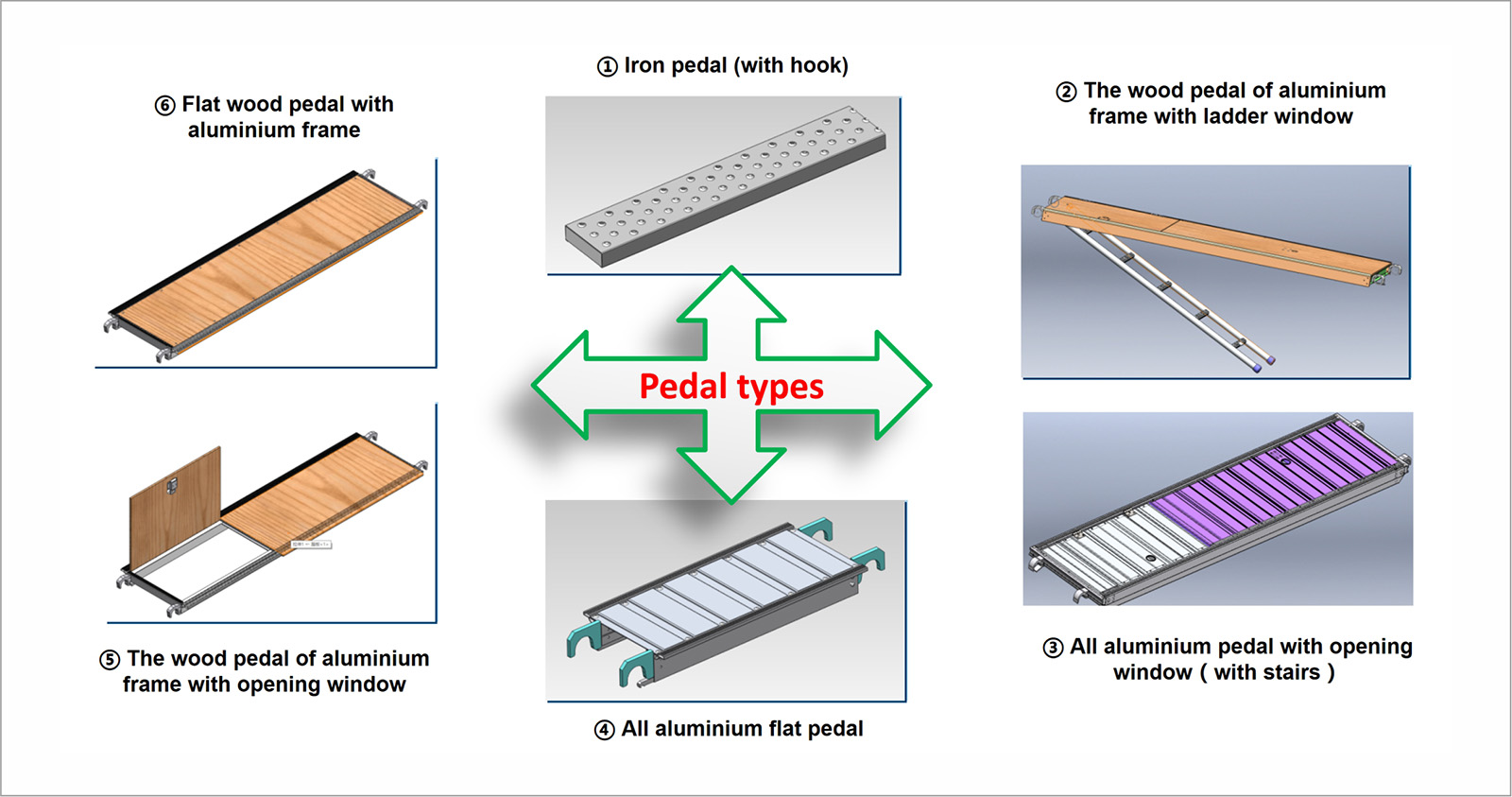

5. Work Platform Pedal

It was fixed on a horizontal brace as work platform for construction and carrying things.it is made of al-alloy frame and plywood. it is with windproof and window opening function. Width: 300 and 600, length is 600~3000, Every 300 is a kind of specification. |

|

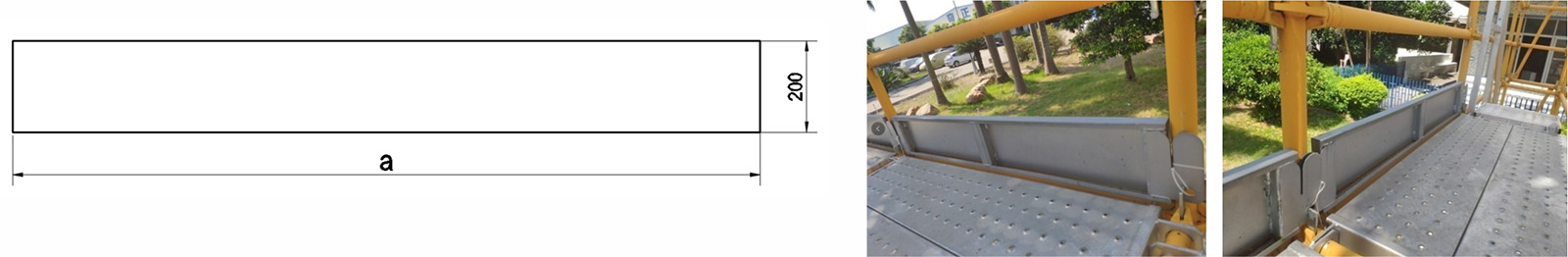

6.Skirtboard

It is placed vertically on the edge of the working platform to prevent personnel from stepping on the foot by mistake or preventing falling objects from hurting people.

Skirt Board TB

a×200

a=300、600、900、1200、1500、1800、2100、2400、2700、3000

a×200

a=300、600、900、1200、1500、1800、2100、2400、2700、3000

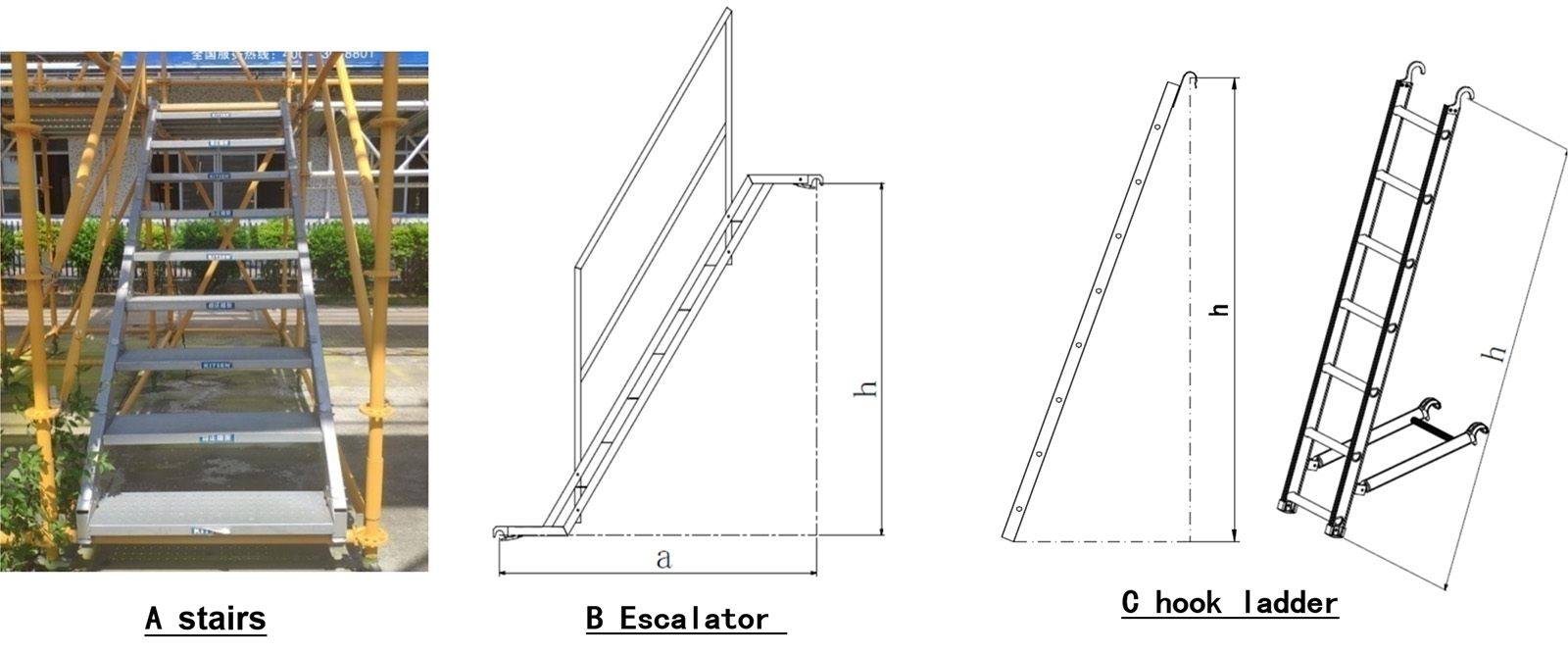

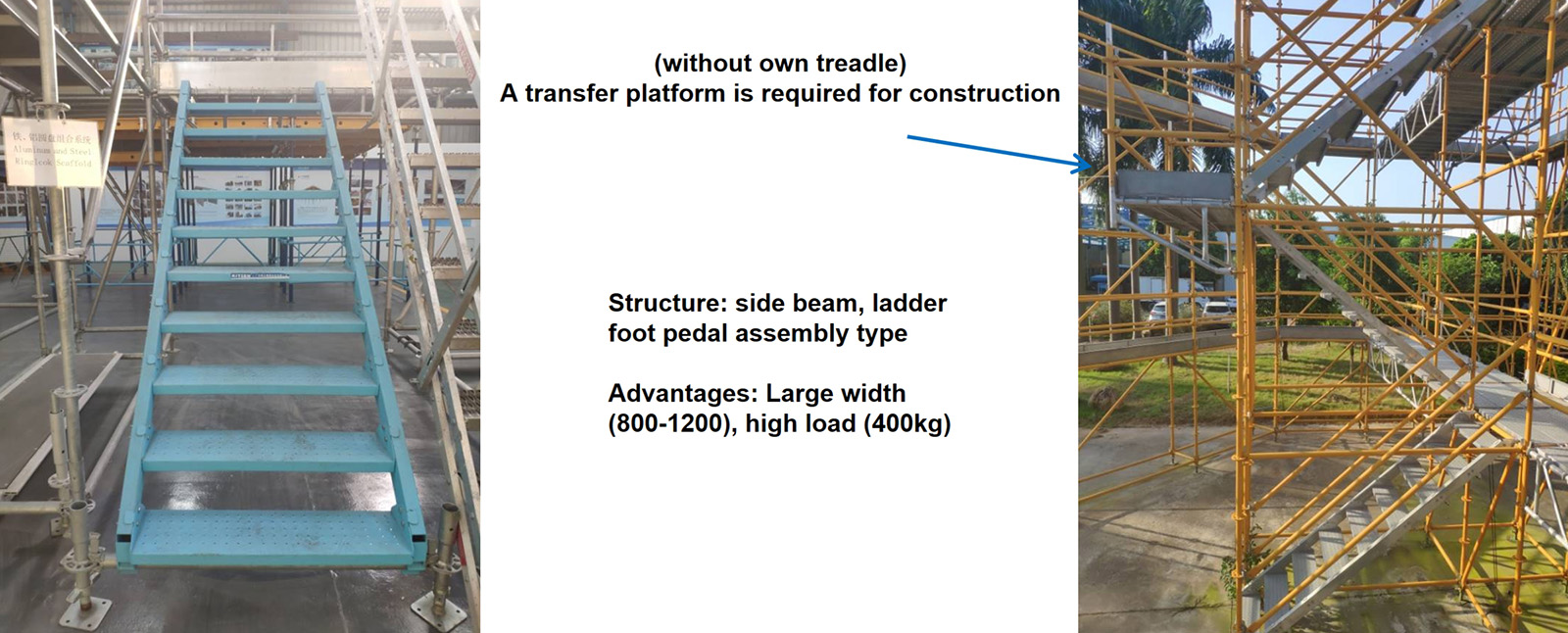

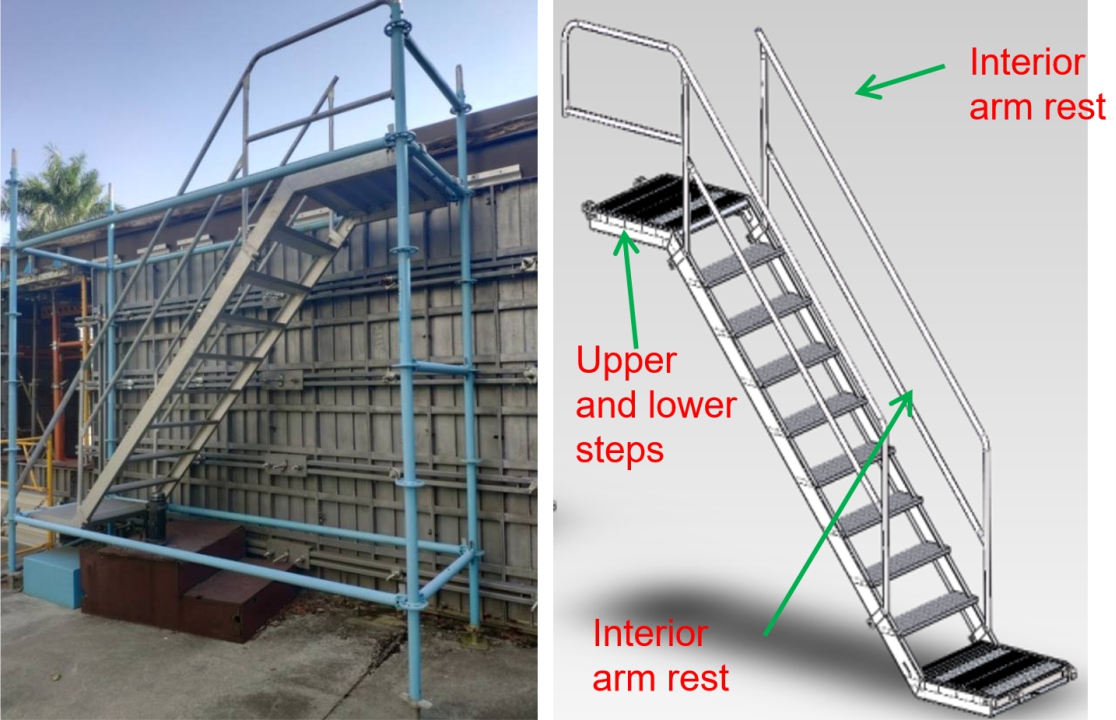

7. Landing Ladder

It is assembled on the horizontal brace for the construction personnel to pass up and down.

A Stairs

B Escalator

|

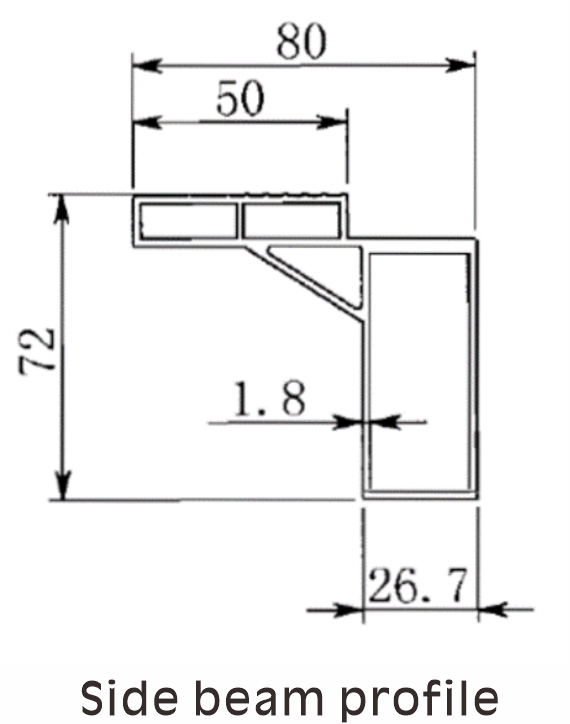

Structure: Ladder steps,Ladder foot pedal, side beam, Inner handrails and outer handrails

Advantages: Span 400-800, high load bearing, fast installation. |

C Hook ladder

|

Structure: The anti-slip bar is riveted between the side beams and hooked on the bar.

Advantages: Span 350-600mm, light weight, fast installation. |

|

|

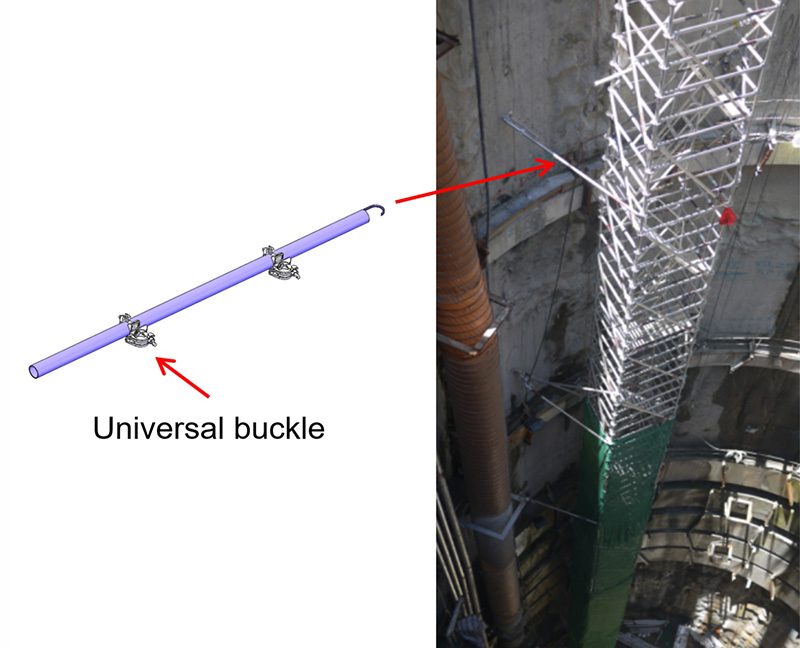

8. Connecting wall pieces

The struts connecting the scaffold to the structure. Function: Increase the stability of the frame and prevent rollover Connecting wall pieces ➜ |

|

|

9 Horizontal truss

A horizontal reinforcement bar is composed of an upper and lower chord welded with a vertical bar fastener, it is used in the scaffold straddle position. Function :(construction) pedestrian, vehicle passage, aircraft, ships, equipment maintenance, etc |

|

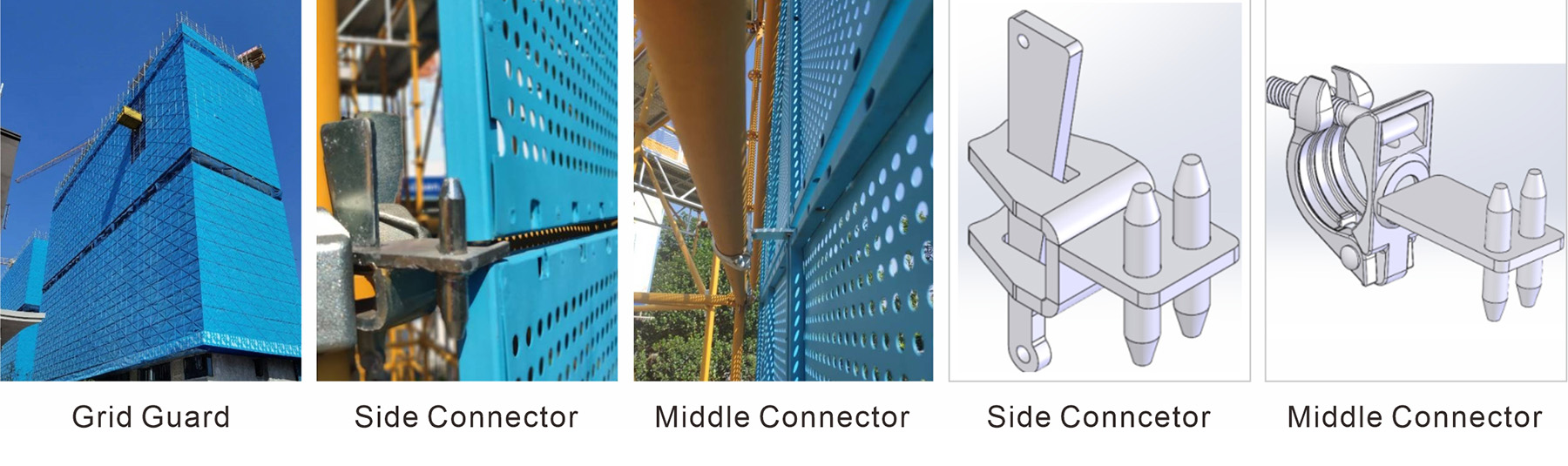

10. Grid Guard

Grid guard is installed on the periphery of the scaffold by means of a connector with a vertical brace and a horizontal brace.

Analysis on Economic Benefit

Economic Benefit Index of Ring Lock Aluminum System

1. It is widely used in the construction of internal and external frames, bridge construction, aerial work platform,

stage construction and construction of special projects.

2. The main body of the product is made of aluminum alloy, installation and disassembly can save more than 50% labor.

3. The Installation does not require professional personnel, the whole process of bolt-free installation, reducing the labor intensity.

4. Under the same load, it can save about 1/3 of the traditional scaffold material, and its use life can reach 15 years.

and the corresponding transportation costs, demolition labor costs, management fees, material loss and other costs will be saved.

2. The main body of the product is made of aluminum alloy, installation and disassembly can save more than 50% labor.

3. The Installation does not require professional personnel, the whole process of bolt-free installation, reducing the labor intensity.

4. Under the same load, it can save about 1/3 of the traditional scaffold material, and its use life can reach 15 years.

and the corresponding transportation costs, demolition labor costs, management fees, material loss and other costs will be saved.

Product Installation and Disassembly

|

|

| 1. The scaffold tower must be operated by at least 2 staff members. For more information on appropriate training, please contact your provider. Apply the brake and install the adjustable caster into the vertical tube. | 2. Install the two horizontal brace in the connecting tray of the vertical brace. See Zoom in view. |

|

|

| 3.Install the horizontal brace and vertical brace upon the picture. | 4. (A) Install the ladder on the horizontal brace. (B) Install temporary work platforms on the horizontal brace of the vertical frame. (C) Erection of diagonal brace on vertical frames. (D) At this stage, the tower is levelled by adjusting the bolts on the casters. |

|

|

| 5. Install triangular diagonal braces on the columns of the moving scaffolding, as shown in the figure. In order to obtain the maximum elongation of the triangle brace, the lower arm should be as close to the level as possible. | 6. When standing on the temporary work platform, increase the frame upward, and install the buckle pin, and ensure that the frame is firmly connected. The buckle pin should be placed once after each frame is installed. |

|

|

| 7. Reinstall the working platform on the applicable height of the horizontal brace. When standing on the first platform, properly install the horizontal brace and diagonal brace as shown. | 8. When standing on the first work platform, install the ladder, horizontal brace, the diagonal brace, and add a temporary work platform, as shown in the picture. |

|

|

| 9. Repeat steps 4-8 until the desired height of the working platform is reached, as shown in Figure 9 | 10. Install guardrail frames in front and back. |

|

11. a) Reposition the temporary work platform on the horizontal brace.

b) Install baseboards. It is forbidden to work on platforms without guardrail. c) Note that the removal sequence of moving scaffolding is reversed. |

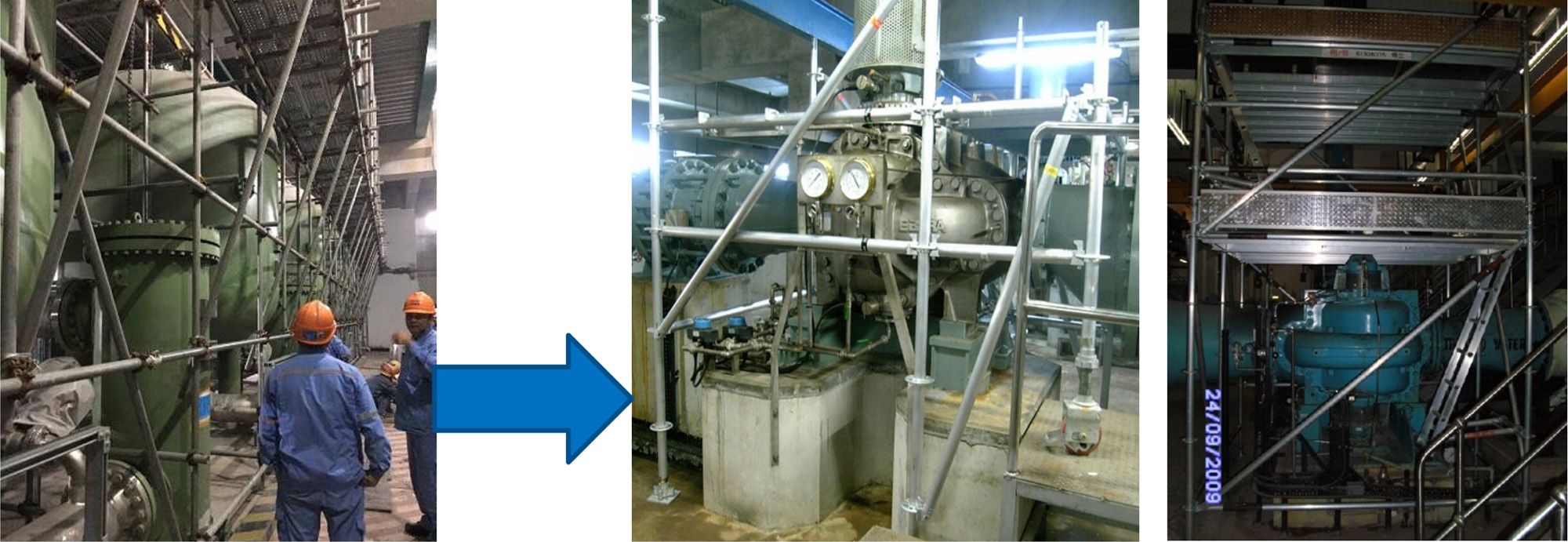

Engineering Projects

| Engineering Projects | Products Use Comparison |

|

The products of current stage on Nuclear Power |

Ring Lock Aluminum Scaffold used in the equipment maintenance, Hongkong, China |

Used in the Exterior Renovation Projects,Aquarium, Hongkong Ocean Garden

Used in the maitenance of Plane, Malaysia Airlines

| Used in the maintenace of Airport, Hongkong | Used in the exterior Wall Decoration, Kuala Lumpur Hotel, Malaysia |