Table Light Steel Formwork/ Al Alloy Formwork

Table Light Steel Formwork

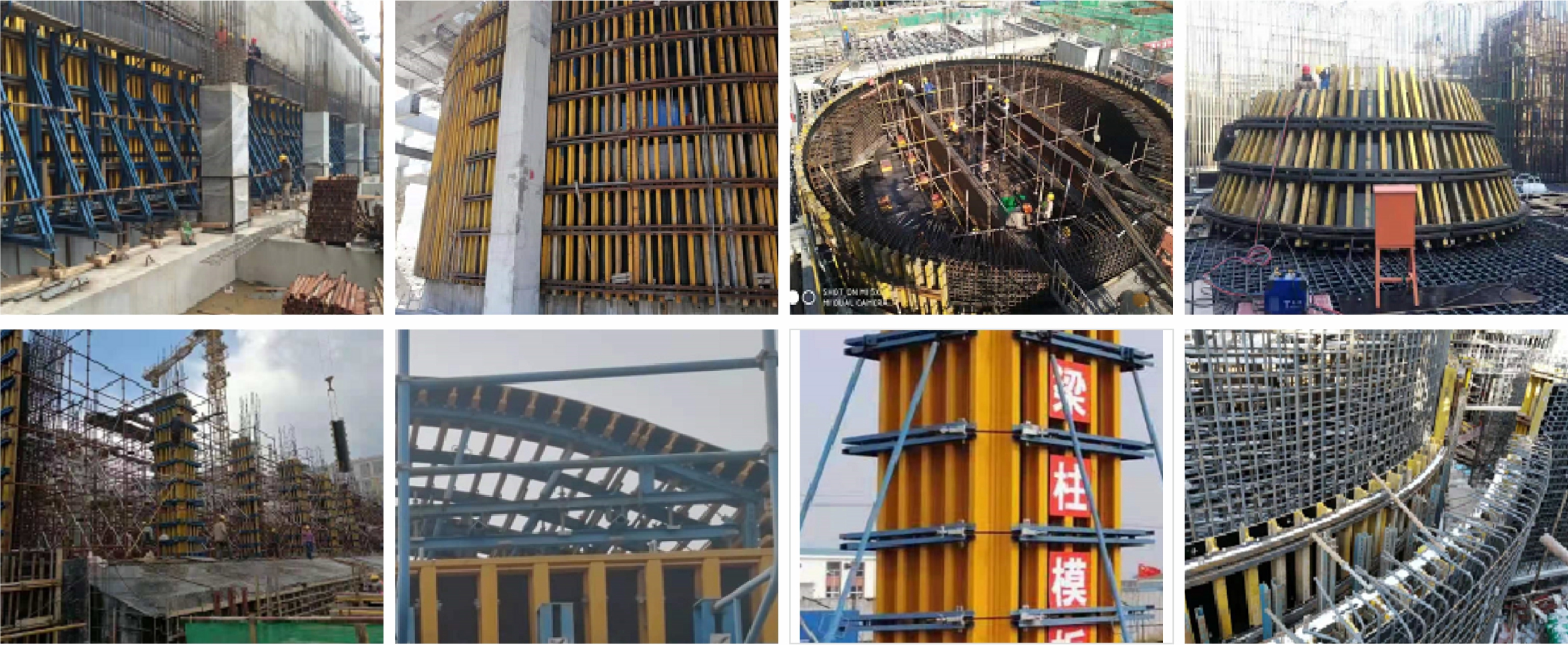

Table Light steel formwork is an alkali-resistant formwork for building construction. It is made from a combination of various profiles formed by cold rolling of alkali-resistant ferritic stainless steel sheet with properties equivalent to Q355 and is made into various specifications by laser welding. It has the advantages of light weight, high strength,good bearing capacity, no release agent, easy cleaning, convenient disassembly, fast construction speed, etc., and will be widely used in construction engineering, bridge engineering,tunnel engineering and other fields.

The main features of light steel formwork are as follows:

1.Light weight: light steel formwork is heavier than all aluminum alloy formwork, which is easy to handle and install.

2.High strength: The strength and stiffness of light steel formwork are high, and it can withstand greater concrete pressure, which is suitable for various types of building structures.

3.Long life: Light steel formwork uses alkali resistant materials, good corrosion resistance, and far longer service life than wood formwork, bamboo formwork and aluminum mold.

4. Convenient disassembly: Light steel template adopts standardized design, unified component size, simple splicing,and aluminum alloy formwork can be interchangeable and mixed, fast disassembly.

5. High construction efficiency: the assembly and disassembly speed of light steel formwork is fast, which can greatly improve the construction efficiency and shorten the project cycle.

6. Environmental protection and energy saving: Light steel templates can be reused, reducing the consumption of wood resources, which is conducive to environmental protection and energy saving.

7. Good economic benefits: Although the initial investment cost of light steel templates is relatively high, between steel and aluminum molds, due to its long service life and high construction efficiency, the comprehensive economic benefits are better than traditional templates.

In short, light steel formwork has great advantages in modern building construction and is an ideal formwork material.

2.High strength: The strength and stiffness of light steel formwork are high, and it can withstand greater concrete pressure, which is suitable for various types of building structures.

3.Long life: Light steel formwork uses alkali resistant materials, good corrosion resistance, and far longer service life than wood formwork, bamboo formwork and aluminum mold.

4. Convenient disassembly: Light steel template adopts standardized design, unified component size, simple splicing,and aluminum alloy formwork can be interchangeable and mixed, fast disassembly.

5. High construction efficiency: the assembly and disassembly speed of light steel formwork is fast, which can greatly improve the construction efficiency and shorten the project cycle.

6. Environmental protection and energy saving: Light steel templates can be reused, reducing the consumption of wood resources, which is conducive to environmental protection and energy saving.

7. Good economic benefits: Although the initial investment cost of light steel templates is relatively high, between steel and aluminum molds, due to its long service life and high construction efficiency, the comprehensive economic benefits are better than traditional templates.

In short, light steel formwork has great advantages in modern building construction and is an ideal formwork material.

Table Light Steel formwork and Al alloy formwork

The design of Table light steel formwork is almost the same as the Al alloy formwork system, it is interchangeable, compatible and used with the aluminum alloy formwork system, its material and processing technology is only changed.

Advantages of Al alloy formwork

1.Shorten construction period: save labor and management costs.

2.Great stability: the load bearing capacity of Al Alloy formwork can reach 60KN/m2.

3.High reuse rate: it can be reused more than 150 times in standard construction.

4.Civilized construction: Accessories can be reused, and after removing the formwork, the whole site is safe, clean and tidy.

5.Wide application range: suitable for walls, horizontal floors, columns, beams, stairs, etc.

6.High construction efficiency and good demoulding effect. Less Joint, high precision, smooth and neat concrete surface.

7.Low-carbon, energy saving and emission reduction.

2.Great stability: the load bearing capacity of Al Alloy formwork can reach 60KN/m2.

3.High reuse rate: it can be reused more than 150 times in standard construction.

4.Civilized construction: Accessories can be reused, and after removing the formwork, the whole site is safe, clean and tidy.

5.Wide application range: suitable for walls, horizontal floors, columns, beams, stairs, etc.

6.High construction efficiency and good demoulding effect. Less Joint, high precision, smooth and neat concrete surface.

7.Low-carbon, energy saving and emission reduction.

The Introduction to the modular Aluminium Formwork System

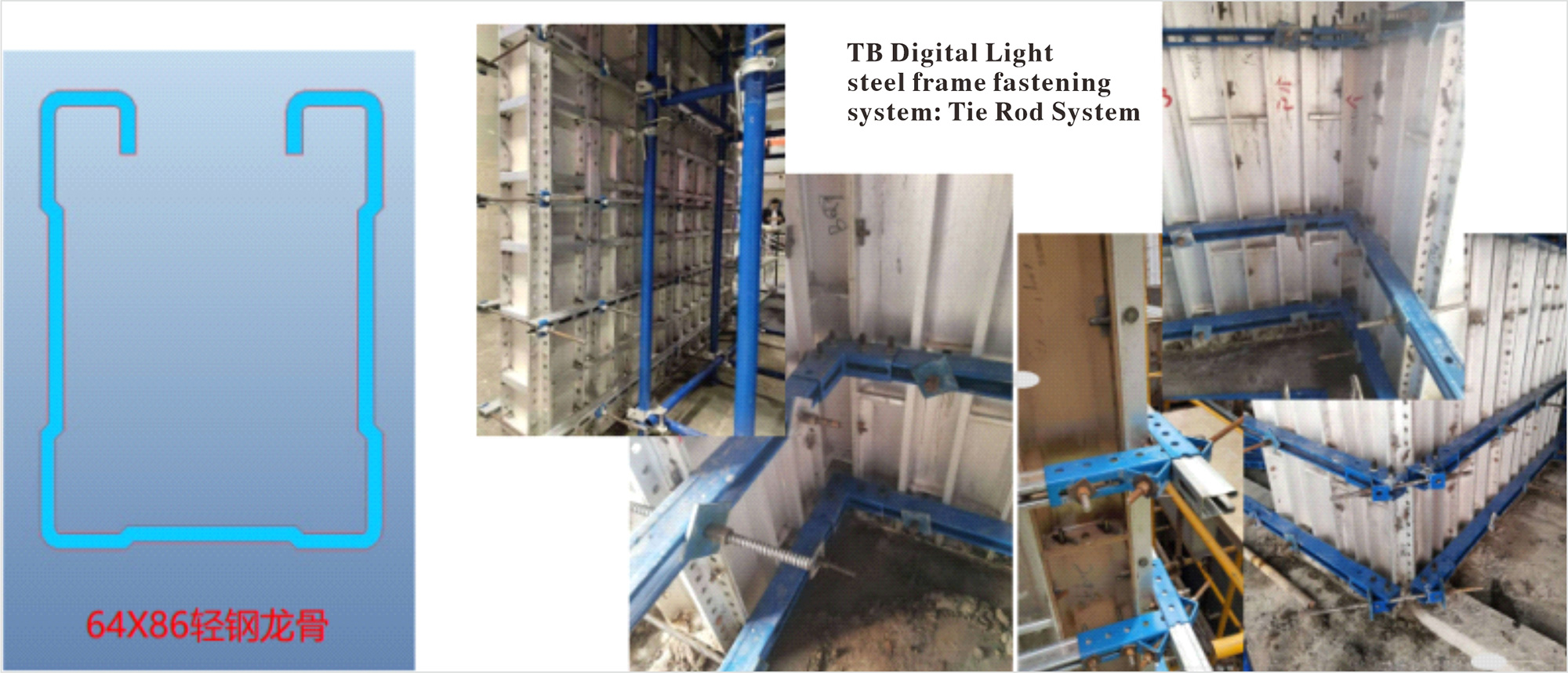

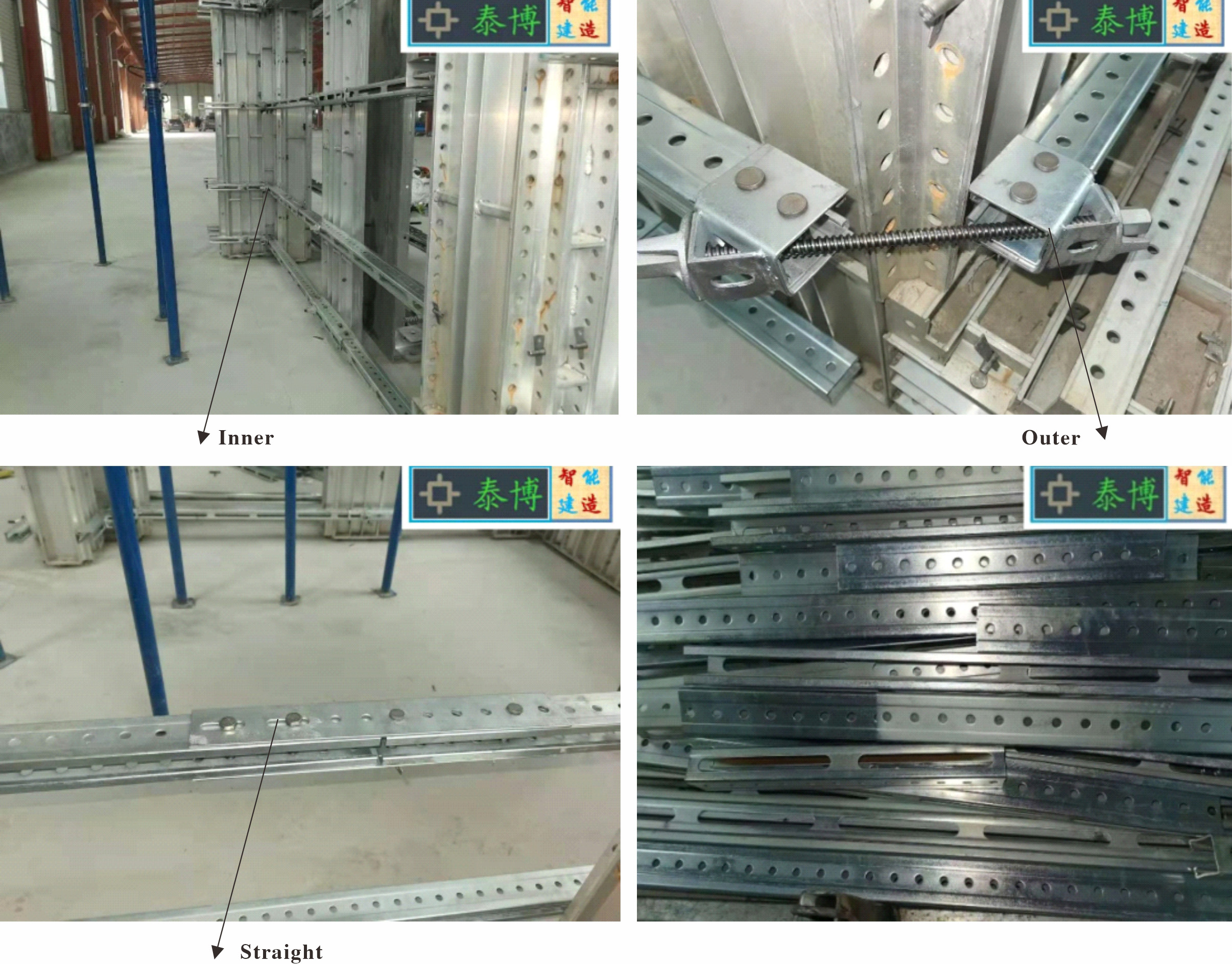

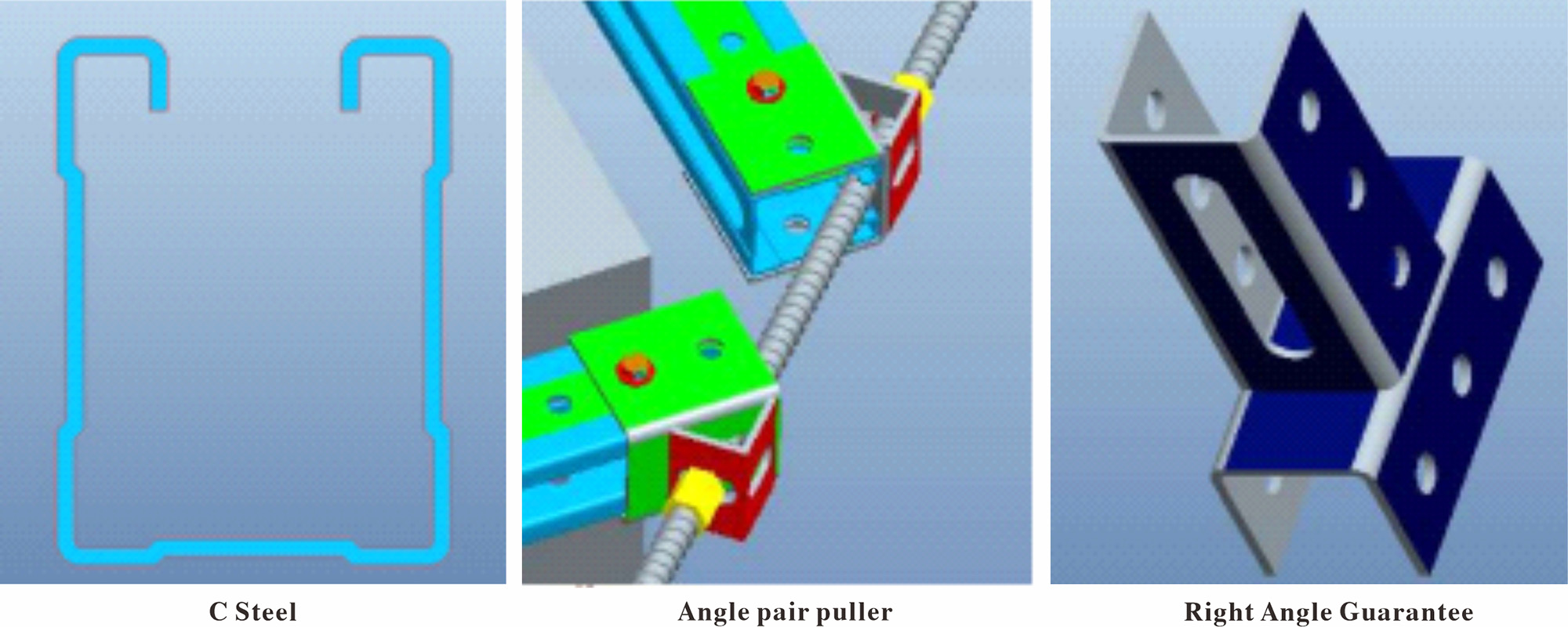

Aluminum alloy formwork system is divided into Tie rod system and pulling system.

The tie rod system is stressed through the steel back (or light steel-frame structure) connected by the through-wall screw, and the pull sheet system is stressed directly through the pull plate.

Formwork system: constitutes the closed surface required for the construction of the concrete structure to ensure the formation of the building structure when the concrete is poured.

Support system: It plays a supporting role in the construction process of concrete structure to ensure the stable support of the floor, beam bottom and cantilever structure.

Fastening system: It is to ensure the structural width and size of the template forming, and there is no deformation, expansion and explosion phenomenon when pouring concrete.

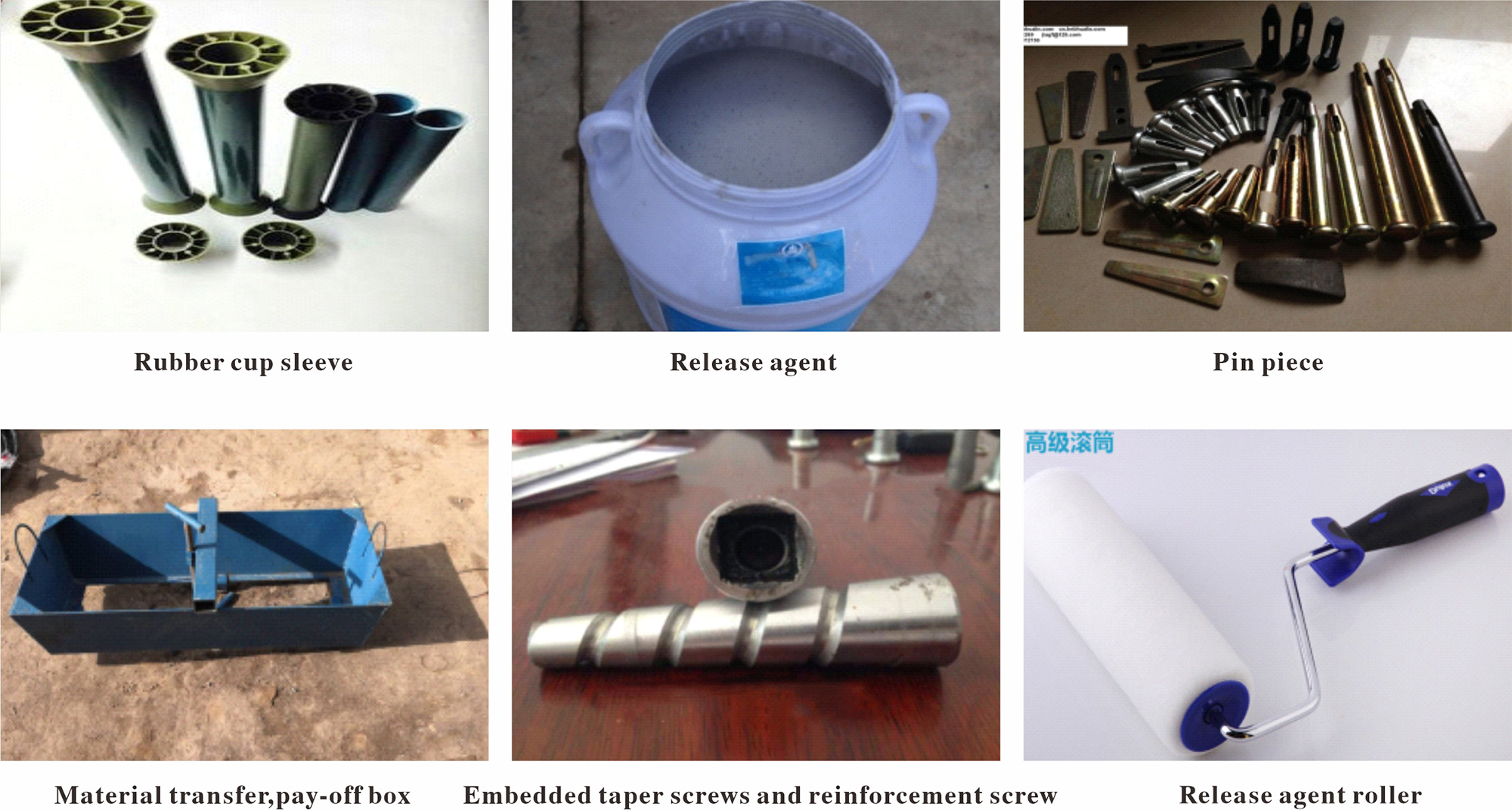

Accessories system: A single panel is connected to the system by accessories system.

The tie rod system is stressed through the steel back (or light steel-frame structure) connected by the through-wall screw, and the pull sheet system is stressed directly through the pull plate.

Formwork system: constitutes the closed surface required for the construction of the concrete structure to ensure the formation of the building structure when the concrete is poured.

Support system: It plays a supporting role in the construction process of concrete structure to ensure the stable support of the floor, beam bottom and cantilever structure.

Fastening system: It is to ensure the structural width and size of the template forming, and there is no deformation, expansion and explosion phenomenon when pouring concrete.

Accessories system: A single panel is connected to the system by accessories system.

Tie Rod System

The tie rod system consists of four parts,such as formwork system, support system, fastening system and accessory system.

In the fastening system, TB has independently developed and patented light steel keel reinforcement system (used to replace the traditional steel back reinforcement system), which can meet the requirements.

Under the premise of safe construction, the weight of the fastening system is greatly reduced, which is convenient for construction.

In the fastening system, TB has independently developed and patented light steel keel reinforcement system (used to replace the traditional steel back reinforcement system), which can meet the requirements.

Under the premise of safe construction, the weight of the fastening system is greatly reduced, which is convenient for construction.

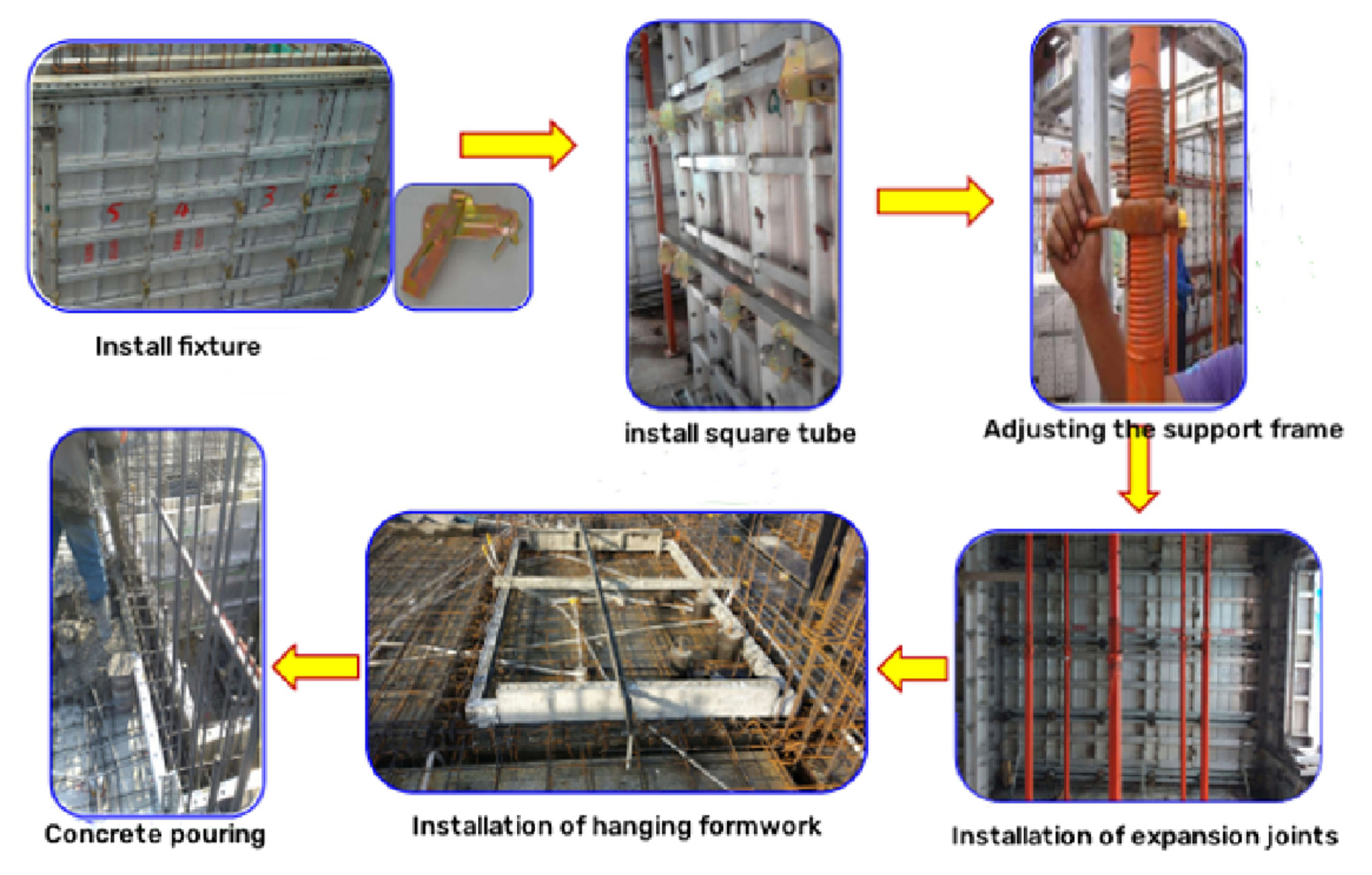

Pulling system included :

Formwork system,Support system,Fastening structure system,Accessory system.

The pulling system is directly stressed by pulling-on pieces.

The pulling system is directly stressed by pulling-on pieces.

1. The installation workers use lighter fixtures and square tubes, which greatly reduces the labor intensity of theinstallation workers and improves the installation efficiency. (Square tube generally 3-10kg/piece)

2. There is no heavy and long back installation, and the safety of installation workers is guaranteed.

3. Taps are Short diagonal bracing, cement nail reinforcement without damage to water and electricity pipes of floor,lighter and smaller than draw bar system , easy to transport, transfer and pass through.

4. It is unnecessary to use the cement support roller, and the tap (sheath) is customized according to the wall thickness to ensure the section size.

5. Special node locations (T-shaped wall, large wall length, wall buttress, etc.) taps can be added at any time, and no other process treatment is required for formworks, which is convenient and fast.

6. When the wall is long, formwork can be installed in a staggered way to ensure that no formwork expansion occurs.

2. There is no heavy and long back installation, and the safety of installation workers is guaranteed.

3. Taps are Short diagonal bracing, cement nail reinforcement without damage to water and electricity pipes of floor,lighter and smaller than draw bar system , easy to transport, transfer and pass through.

4. It is unnecessary to use the cement support roller, and the tap (sheath) is customized according to the wall thickness to ensure the section size.

5. Special node locations (T-shaped wall, large wall length, wall buttress, etc.) taps can be added at any time, and no other process treatment is required for formworks, which is convenient and fast.

6. When the wall is long, formwork can be installed in a staggered way to ensure that no formwork expansion occurs.

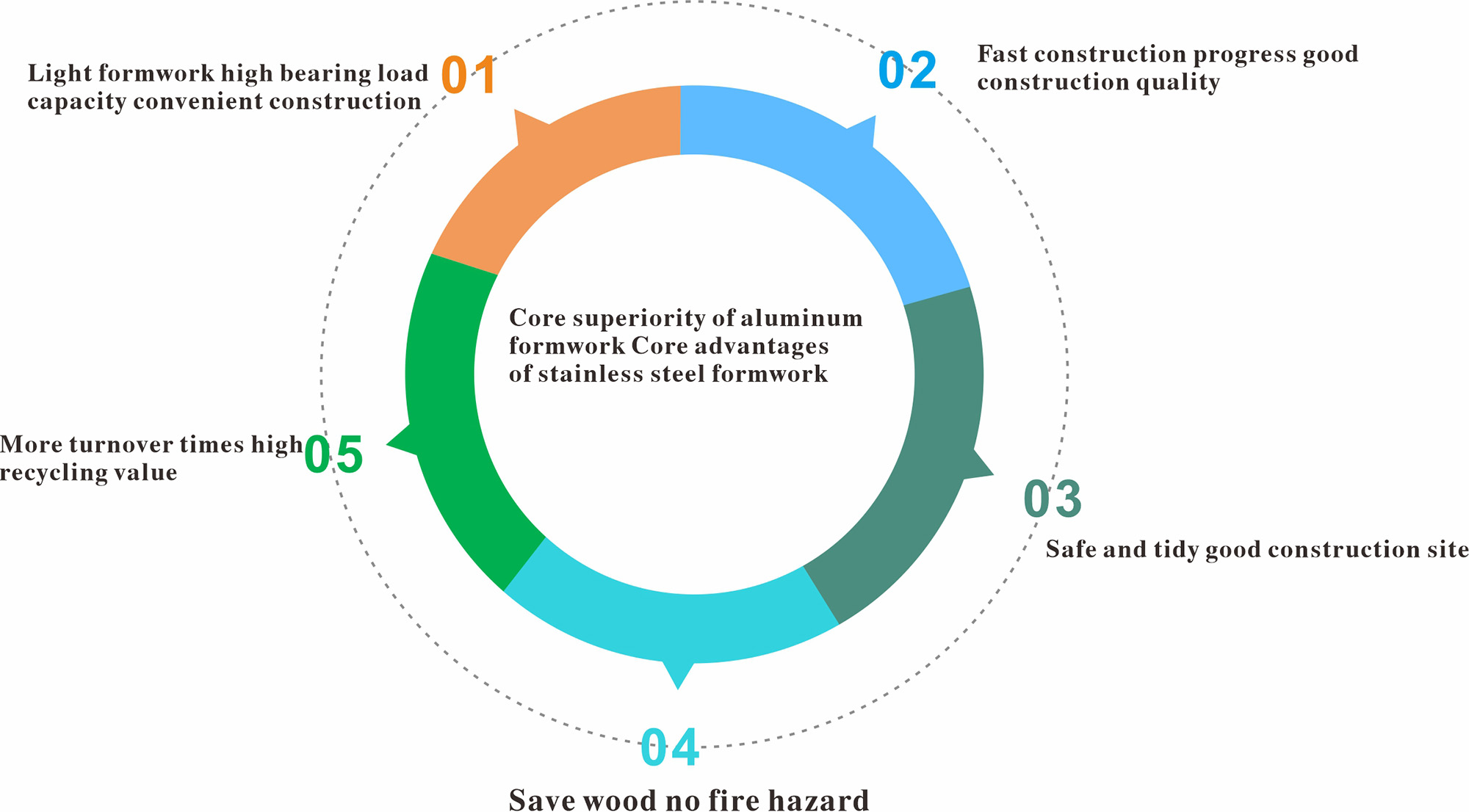

core superiority of aluminum formwork Core advantages of stainless steel formwork

Features of aluminum alloy formwork

1.Integral pouring and one-time molding,Shorten the construction period (standard construction period 4-5 days); Ensure the overall strength of the building, and the turnover service life can reach more than 300 times.

2.Reduce the dependence of quality on workers' technical level; Good construction effect and accurate size; It is smooth and clean, reaching the effect of clean wall, and reducing the cost of secondary plastering.

3.The installation is simple and easy to learn, and the operation is simple, which can solve the problems of woodworking shortage and high cost.

4.With high strength and light weight, it can be assembled and transferred manually without relying on lifting machinery, and has wide adaptability, reducing tower crane occupation and transportation equipment operation costs .

5.The early stripping technology can be used to complete the whole building construction with one set of formwork and three sets of supports.

6.High construction efficiency, skilled workers can assemble and disassemble more than 30 square meters per working day.

7.The effect of civilized construction is obvious, the site is clean, and there is no waste wood formwork.

8.No need use nails to avoid safety accidents such as stabbing hands and feet of on-site personnel.

9.All aluminum material, no rust, easy to keep; There is no potential fire hazard.

10.With high recycling value, aluminum alloy materials can be recycled all the time, in line with the national policies of low-carbon environmental protection, green buildings and circular economy.

2.Reduce the dependence of quality on workers' technical level; Good construction effect and accurate size; It is smooth and clean, reaching the effect of clean wall, and reducing the cost of secondary plastering.

3.The installation is simple and easy to learn, and the operation is simple, which can solve the problems of woodworking shortage and high cost.

4.With high strength and light weight, it can be assembled and transferred manually without relying on lifting machinery, and has wide adaptability, reducing tower crane occupation and transportation equipment operation costs .

5.The early stripping technology can be used to complete the whole building construction with one set of formwork and three sets of supports.

6.High construction efficiency, skilled workers can assemble and disassemble more than 30 square meters per working day.

7.The effect of civilized construction is obvious, the site is clean, and there is no waste wood formwork.

8.No need use nails to avoid safety accidents such as stabbing hands and feet of on-site personnel.

9.All aluminum material, no rust, easy to keep; There is no potential fire hazard.

10.With high recycling value, aluminum alloy materials can be recycled all the time, in line with the national policies of low-carbon environmental protection, green buildings and circular economy.

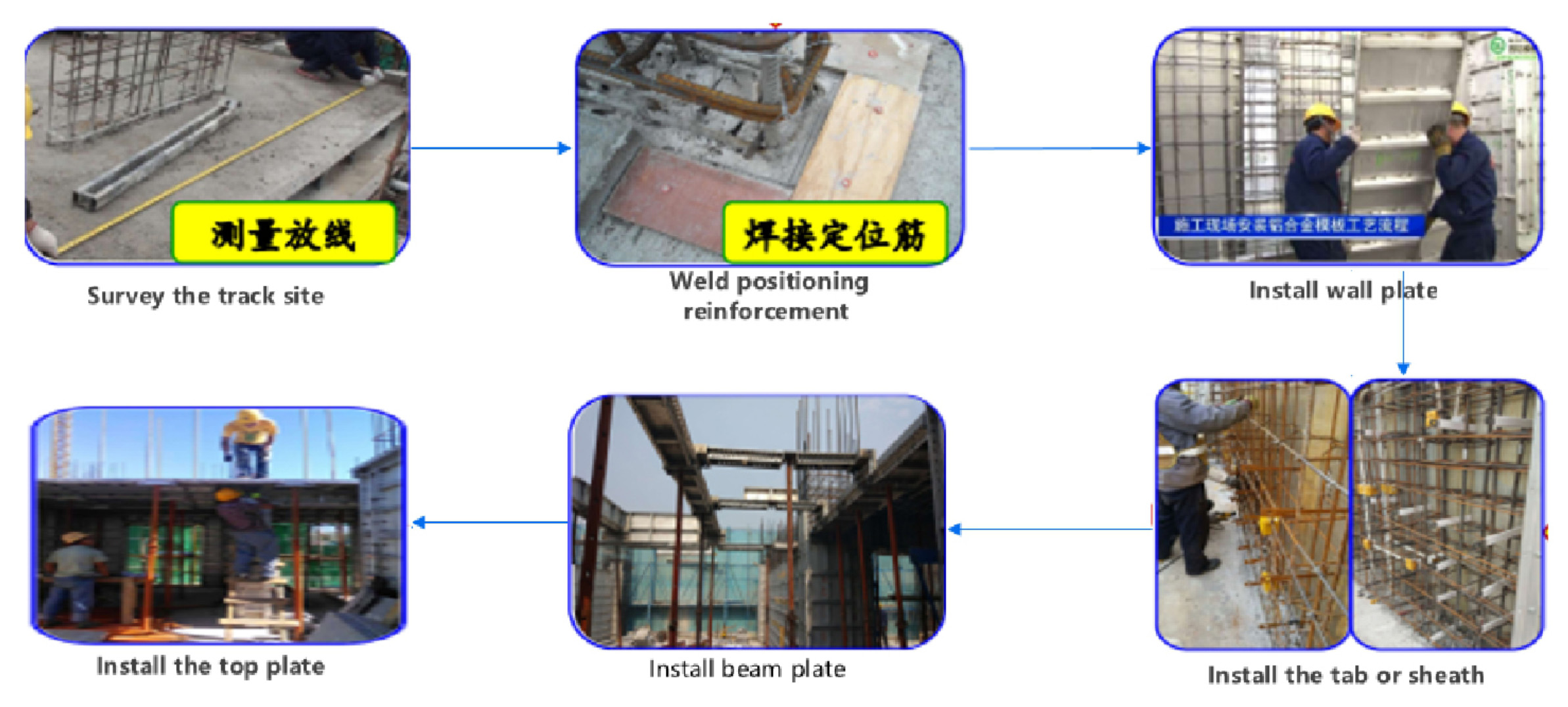

Aluminum formwork installation process

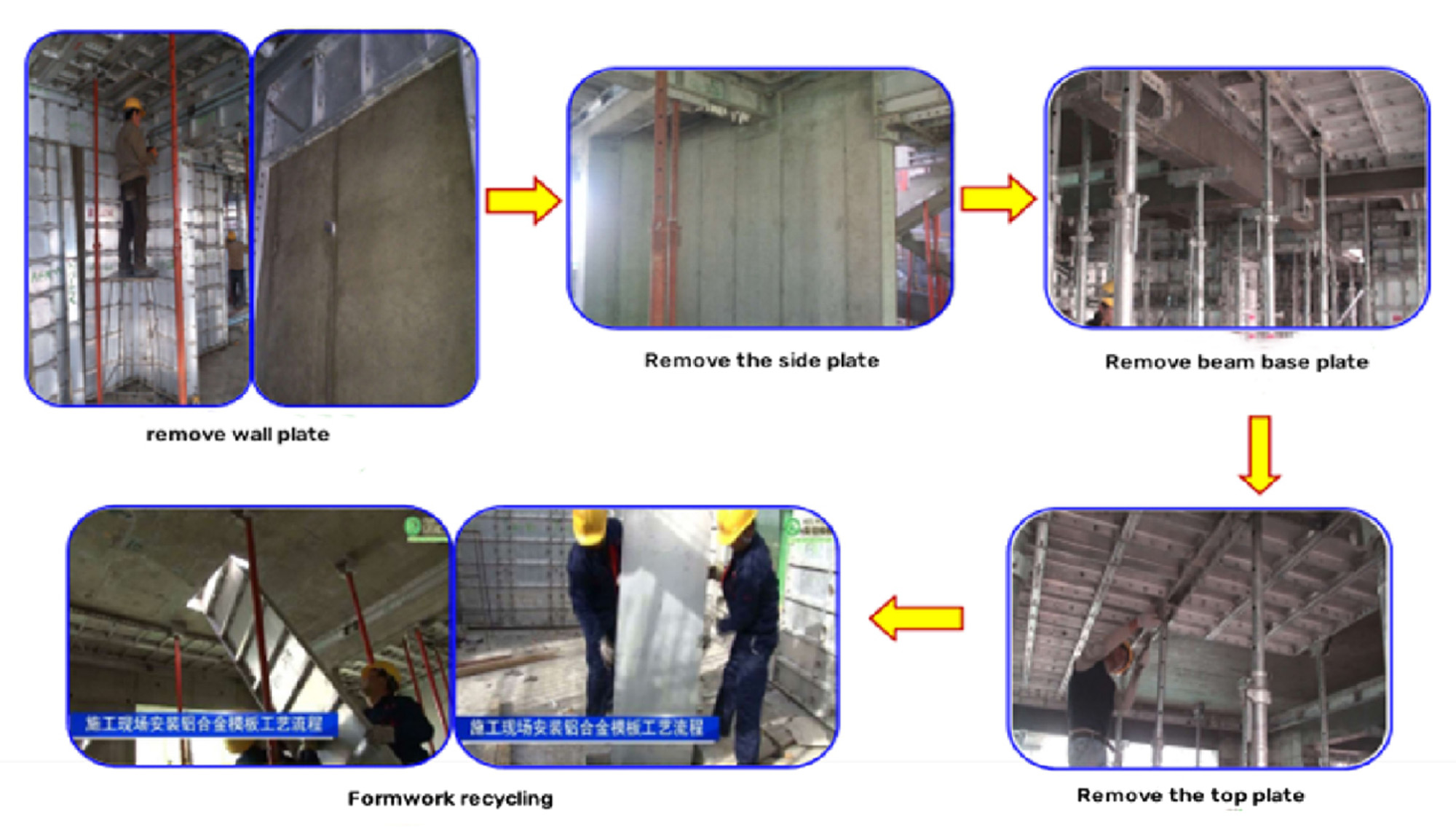

Aluminum formwork removal process

Table Lightweight Steel Formwork System

Table Lightweight Steel Formwork System and Al Alloy Formwork System

1.compatible, interchangeable and mixed use.

2. The construction and fittings are identical.

Table is committed to the research, development and test of Table lightweight steel formwork, and has finally produced a complete system that is more practical and lower in cost than aluminum formwork.

1.compatible, interchangeable and mixed use.

2. The construction and fittings are identical.

Table is committed to the research, development and test of Table lightweight steel formwork, and has finally produced a complete system that is more practical and lower in cost than aluminum formwork.

Site Application