TB Hydraulic Core Lifting System

TB Hydraulic Core Lifting System is powered by the heavy duty and long-stroke double-acting cylinder, while guarantees the bearing capacity of steel girder platform system, at the same time reduces the number of stand

posts to 3-4 numbers. With the precise hydraulic control system, keeps the synchronous jacking of multiple cylinders with minimum error possible during the site operation. The technology features in its overall system

lifting, lower post-standing position and computerized hydraulic control self-climbing, and boasts itself in popular application of super high rising building above 200m especially, as well as other core structure like grain silo etc.

Features Of The System

◆ The whole system makes an independent, closed and secured operating space.

◆ The steel trusswork is not only used for hanging wall formwork panel and suspended platform, but also material storage area and other machinery attachment on the trusswork platform (with a bearing capacity of 10KN/m2).

◆ The whole platform, wall formwork and suspended platform are self-climbing through the hydraulic mechanism, which requires less tower crane work and less labor, enhancing the working efficiency.

◆ The 4 standing struts are set on the well-cured concrete with maximum capacity, which secured the working process.

◆ The system is highly adaptable with adjustable features according to the section or structure variation within the graphic area.

◆ The whole trusswork is set on top of structural walls, which insured the maximum safety by preventing the system from falling.

◆ Precise hydraulic control system keeps the synchronous jacking of multiple cylinders, with minimum error possible during the jacking process.

◆ Fast construction speed, it takes only 2-3 hours to do jacking each time, only 2-3 days to complete 1 floor.

◆ The steel trusswork is not only used for hanging wall formwork panel and suspended platform, but also material storage area and other machinery attachment on the trusswork platform (with a bearing capacity of 10KN/m2).

◆ The whole platform, wall formwork and suspended platform are self-climbing through the hydraulic mechanism, which requires less tower crane work and less labor, enhancing the working efficiency.

◆ The 4 standing struts are set on the well-cured concrete with maximum capacity, which secured the working process.

◆ The system is highly adaptable with adjustable features according to the section or structure variation within the graphic area.

◆ The whole trusswork is set on top of structural walls, which insured the maximum safety by preventing the system from falling.

◆ Precise hydraulic control system keeps the synchronous jacking of multiple cylinders, with minimum error possible during the jacking process.

◆ Fast construction speed, it takes only 2-3 hours to do jacking each time, only 2-3 days to complete 1 floor.

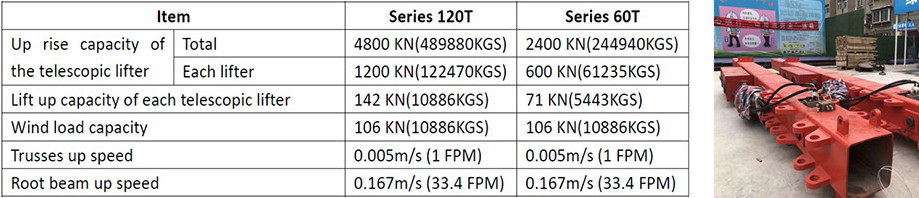

Specifications of Different Series

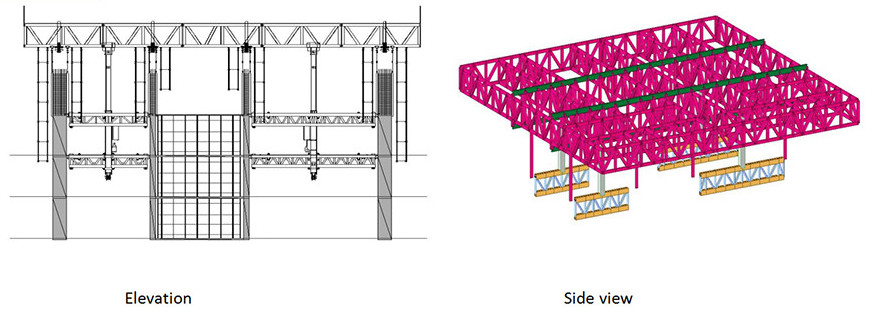

Layout design

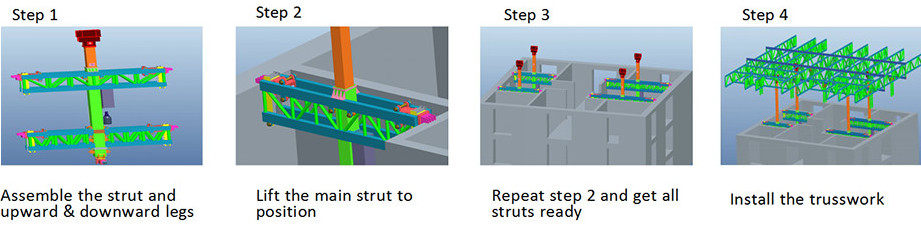

Installation

Site Application