Lightweight Modular Residence Building Machine

|

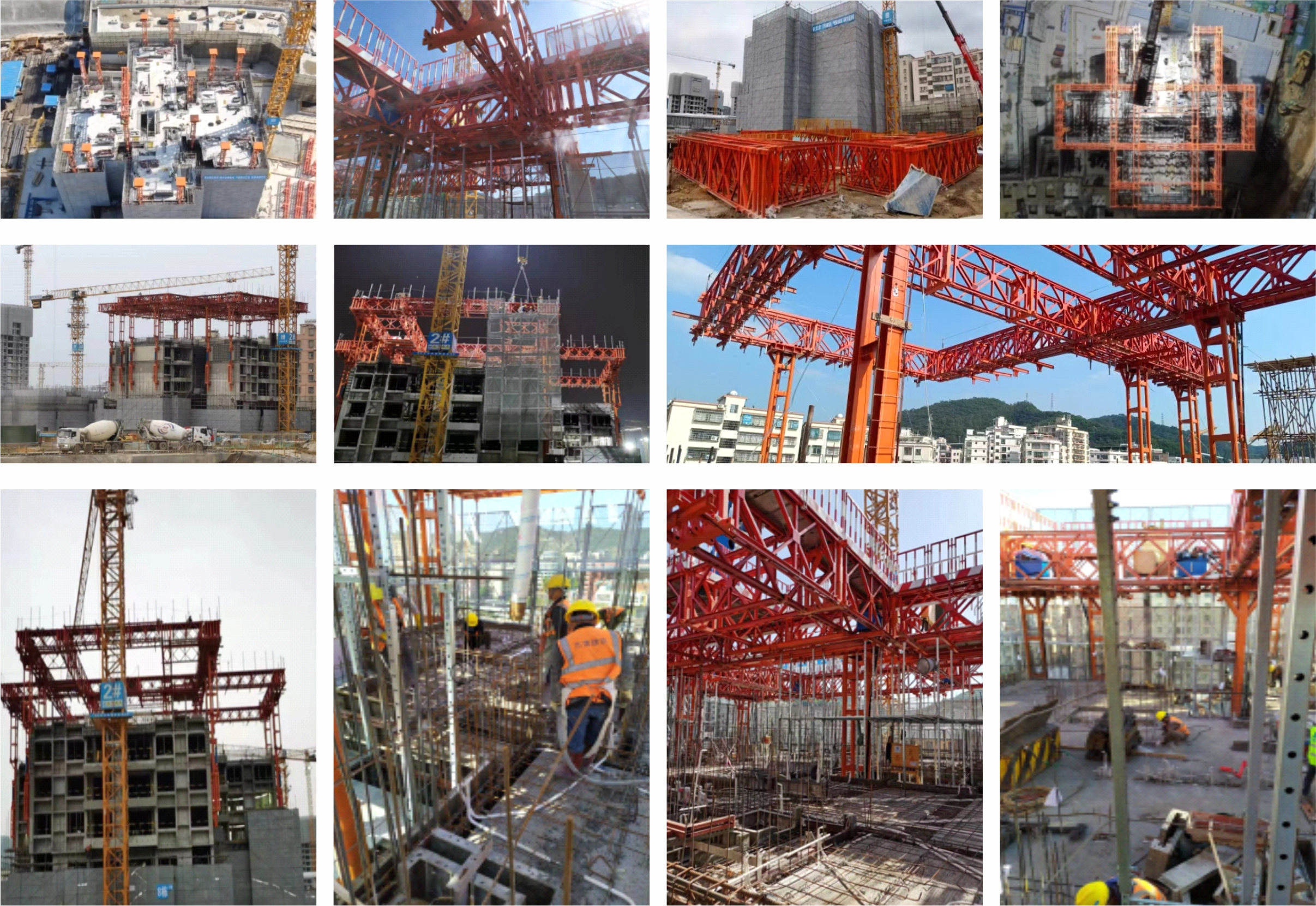

Upon the concept of integration of super high-rise heavy duty construction equipment, through lightweight and standardized innovation, a lightweight construction operation integrated platform (light residential top formwork) suitable for residential shear wall structure is developed. The weight of the platform is controlled within 300 tons,and the equipment turnover rate is more than 90%.

· Equipment construction integrated function

· Safe and efficient lifting function · Concrete efficient spreader function · Concrete spray curing function · All-weather construction is supported · construction elevator construction layer |

|

|

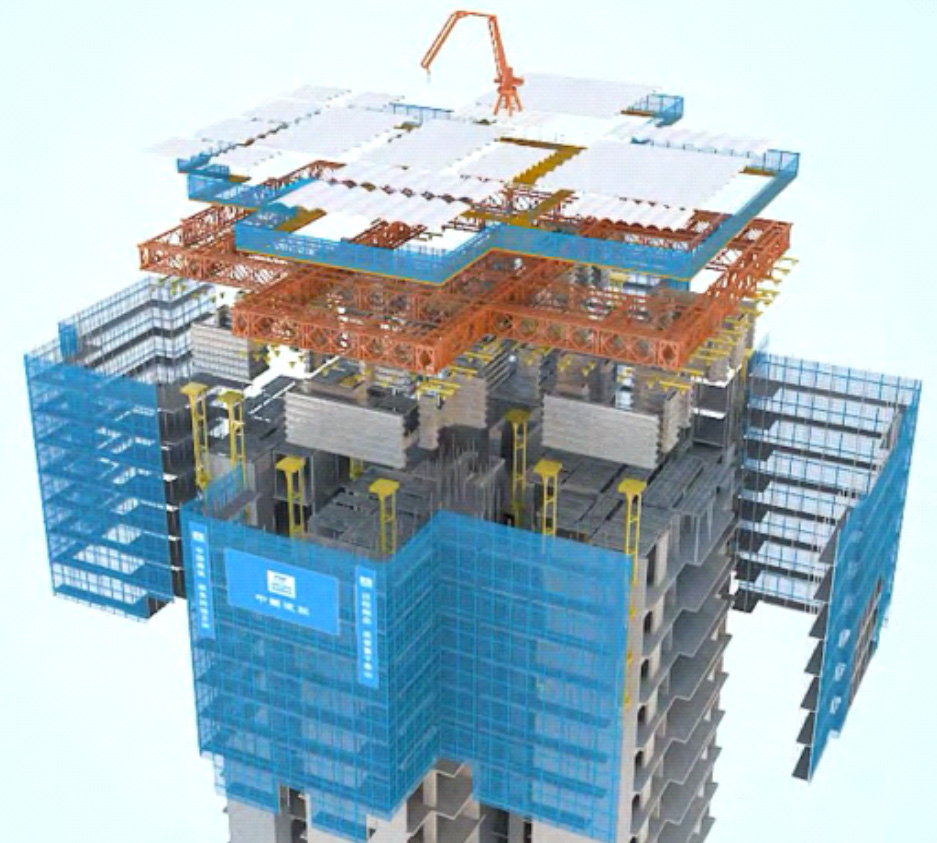

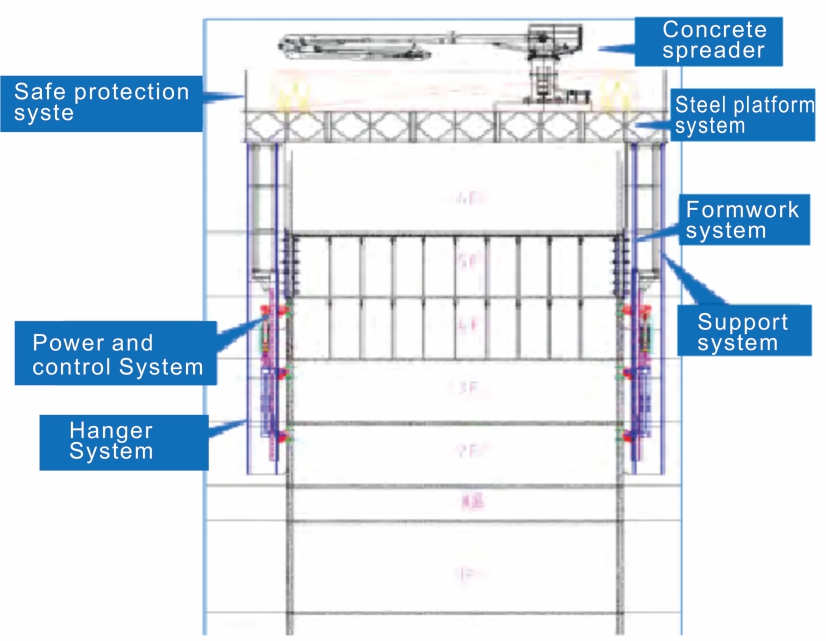

System Components

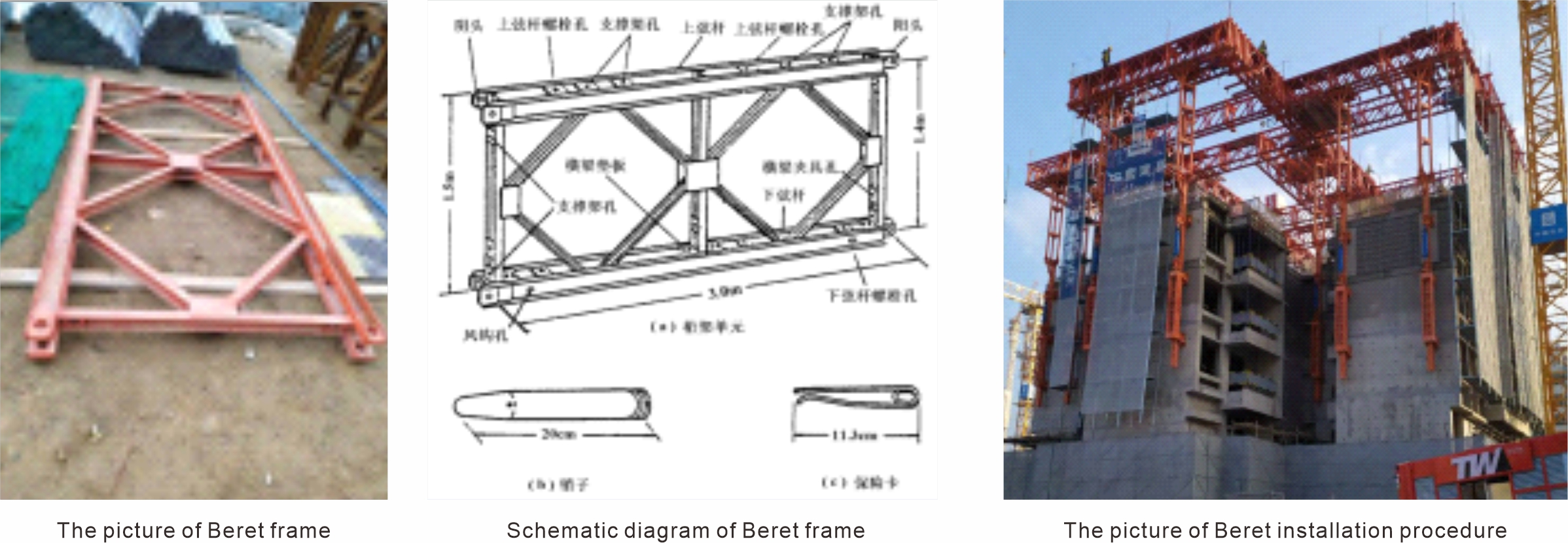

Steel platform system: 321 type Beret frame connection (L 300X H 150CM);

Support system: guide rail column, gate brace column and wall guide;

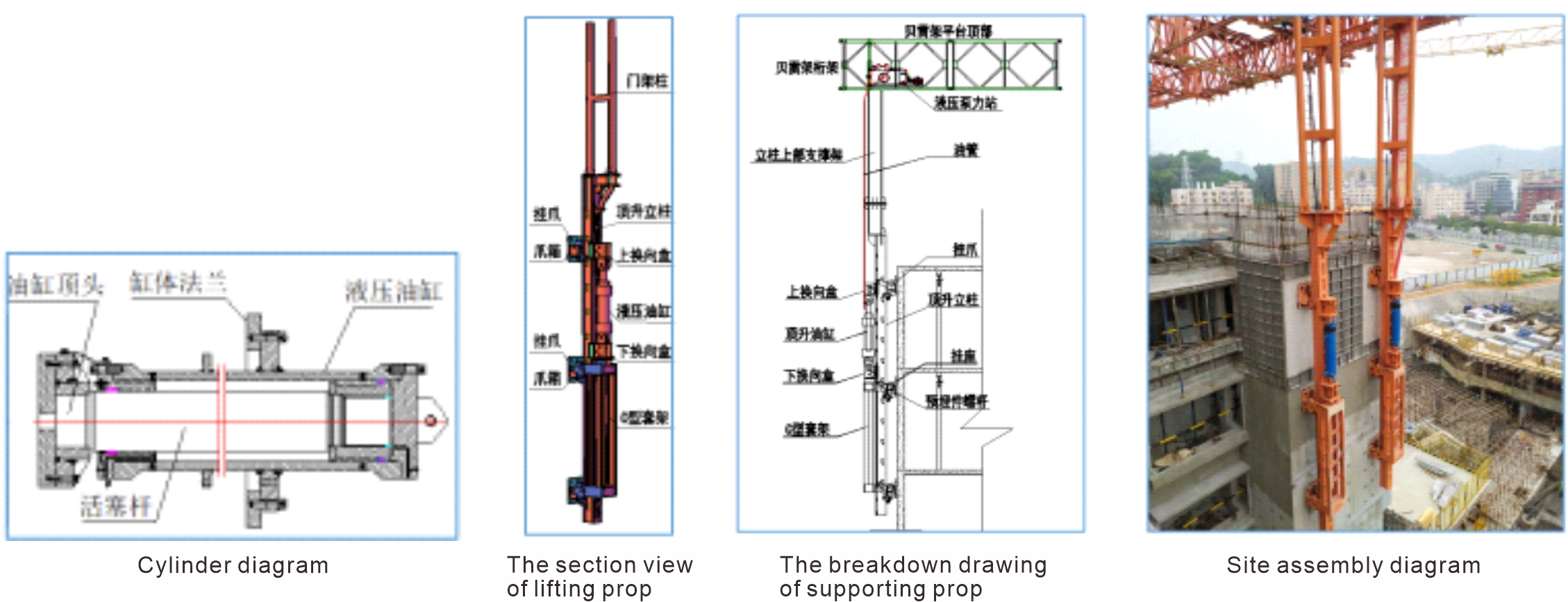

Power and control system: small stroke, small tonnage hydraulic cylinder;

Formwork system: Aluminum alloy formwork;

Hanger system: Light hanger;

Safety protection system: upper platform protection, track plate

|

1) "Hanging" intelligent building machine

It consists of the top platform and steel truss system, the "suspended" support and hydraulic jacking system, the electric control system, the internal and external pylon system, the formwork system and the whole process safety protection system. It belongs to the large-process cylinder support system with few fulcrum, and the support main column driven by hydraulic cylinder is cantilevered on the lower wall and the lower wall. On the use of lightweight design concept. With light components, small weight, strong bearing capacity, strong integration ability, elevator direct platform. Jacking, installation and demolition, construction speed is fast. Easier operation, increased reliability and reduced risk. Our early projects, basically using this "hanging" intelligent construction machine, such as Changsha Delta Beichen timber, Xi 'an Rongmin Financial Center project.

|

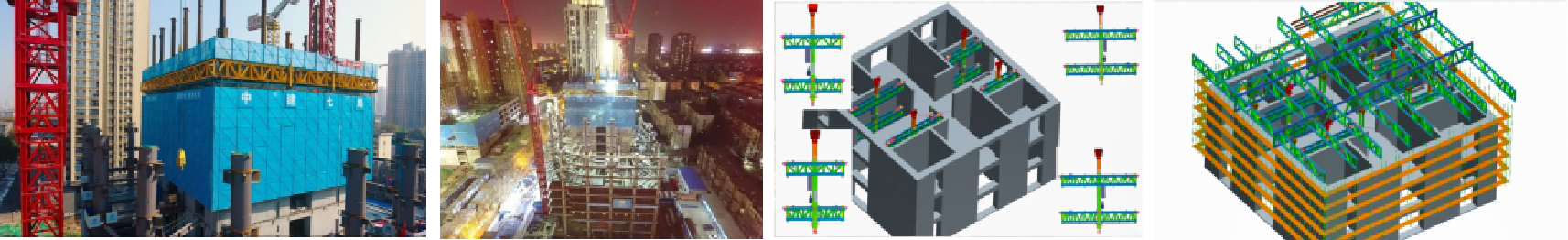

2) "attached" intelligent building machine

The "attached" building machine, that is, the construction of the residential intelligent construction platform system, hangs the template of the vertical structure under the steel platform, adopts the multi-fulcrum wall hanging support system, attaches to the wall, and lifts the upper steel platform system to drive the formwork system and the hanger system to rise together, thus completing the construction of the vertical concrete structure. Good safety, fast construction speed, large bearing capacity, strong adaptability, all-weather operation. We have adopted this approach for our residences on the Yihe New Town project in Chengdu.

|

|

3) "floor type" intelligent building machine

The "floor type" intelligent construction machine ADAPTS to the structure of about 100 meters in height, which can be used for house construction and large infrastructure, and is also the basic idea for the future demolition machine. The supporting main columns, driven by hydraulic cylinders, sit on the ground (not on the structure) and lift from the steel truss platform that climbs above them, from which the vertical formwork and pylon are suspended. Mainly used for vertical wall structure construction and safety protection at this stage, the use of "lightweight" design concept, the whole system can provide enough lifting force and resist 12 strong winds, the use of advanced intelligent control and monitoring system. We have been applied in Dashixia project, the project used two sets, the use of "light steel stainless template" as a supporting formwork system.

System Functions

Hydraulic cylinder with small stroke and small capacity, supporting column and hanger are used as the lifting and supporting system of the formwork, the steel platform system on the upper part of the external wall hanger support system is lifted to drive the formwork system and hanger system to rise together, so as to complete the vertical concrete structure construction.

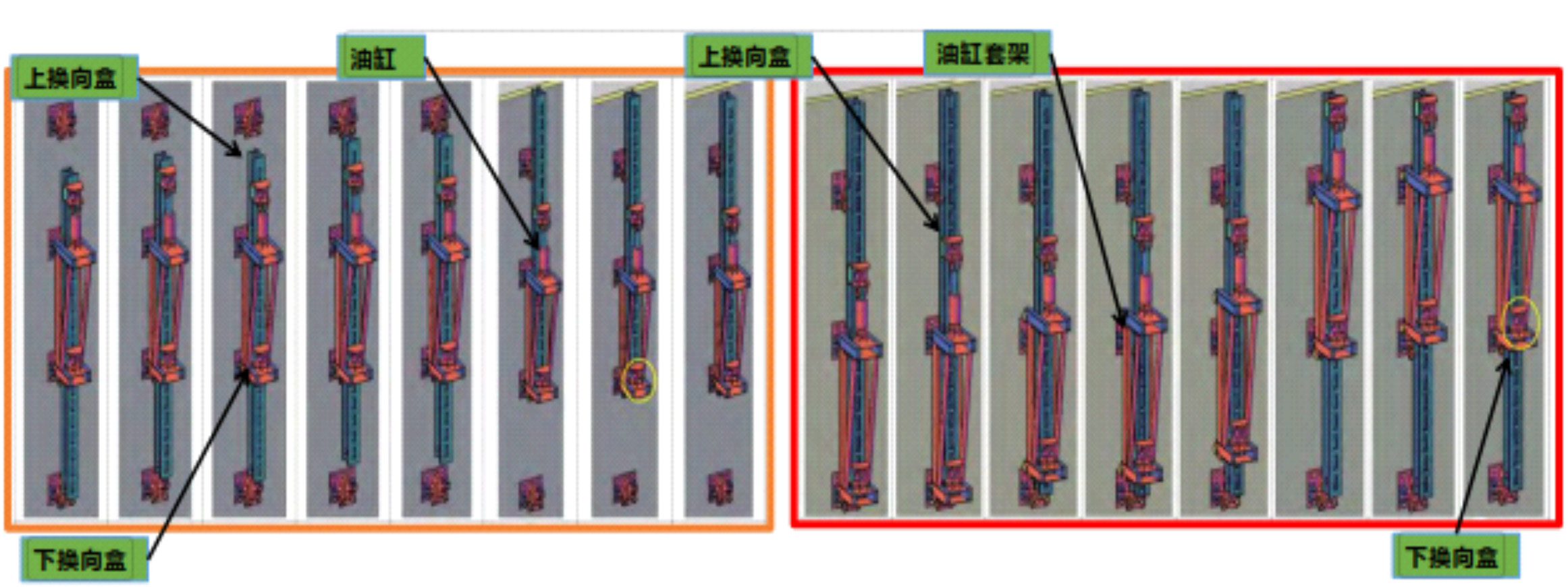

Working principle of climbing operation

The platform and cylinder liner can climb each other by using the jacking and pullingof the cylinder and the switching of the

up-down reversing box. Take 3m's residential building as an example: the short stroke can be divided into 0.3mx10 times, and the cylinder is lifted 10 times to complete a climb. Cylinder speed is 10mm/s.

Cylinder technical parameters

lifting capacity: 70t; Maximum travel: 800mm;

lifting speed: 10mm/s;

cylinder tension: 10t

Self-locking function: power off or voltage loss

Beret frame parameters

Size: 300x150cm;Single weight: 270kg;

Material: 16# Mn steel.

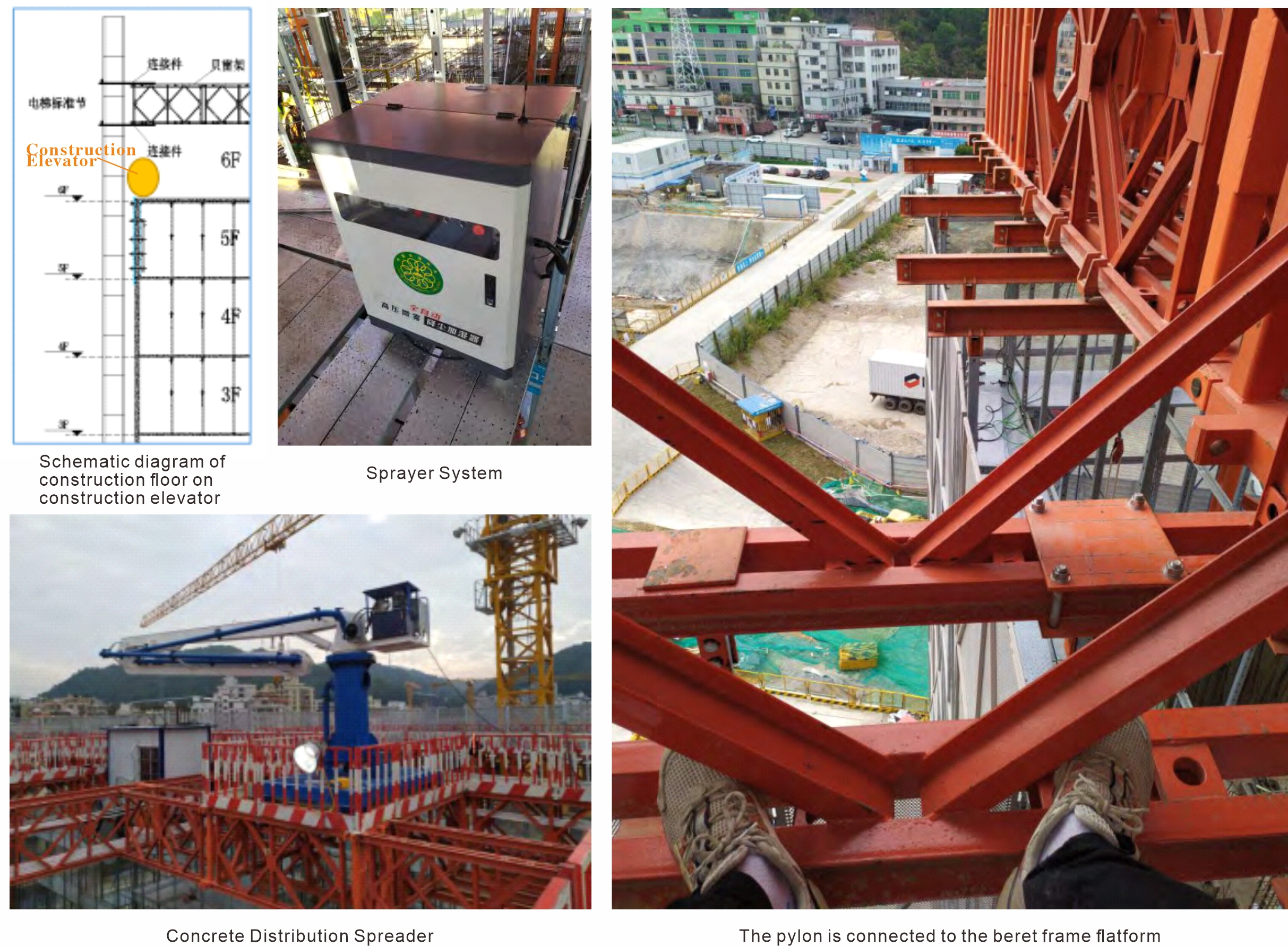

Other functions of platform

hanger: hanger, vertical force, safer; template: Hanging gable and elevator shaft opening template;

Cloth machine: synchronous lifting with the platform;

Construction elevator: to reach the top of the construction layer;

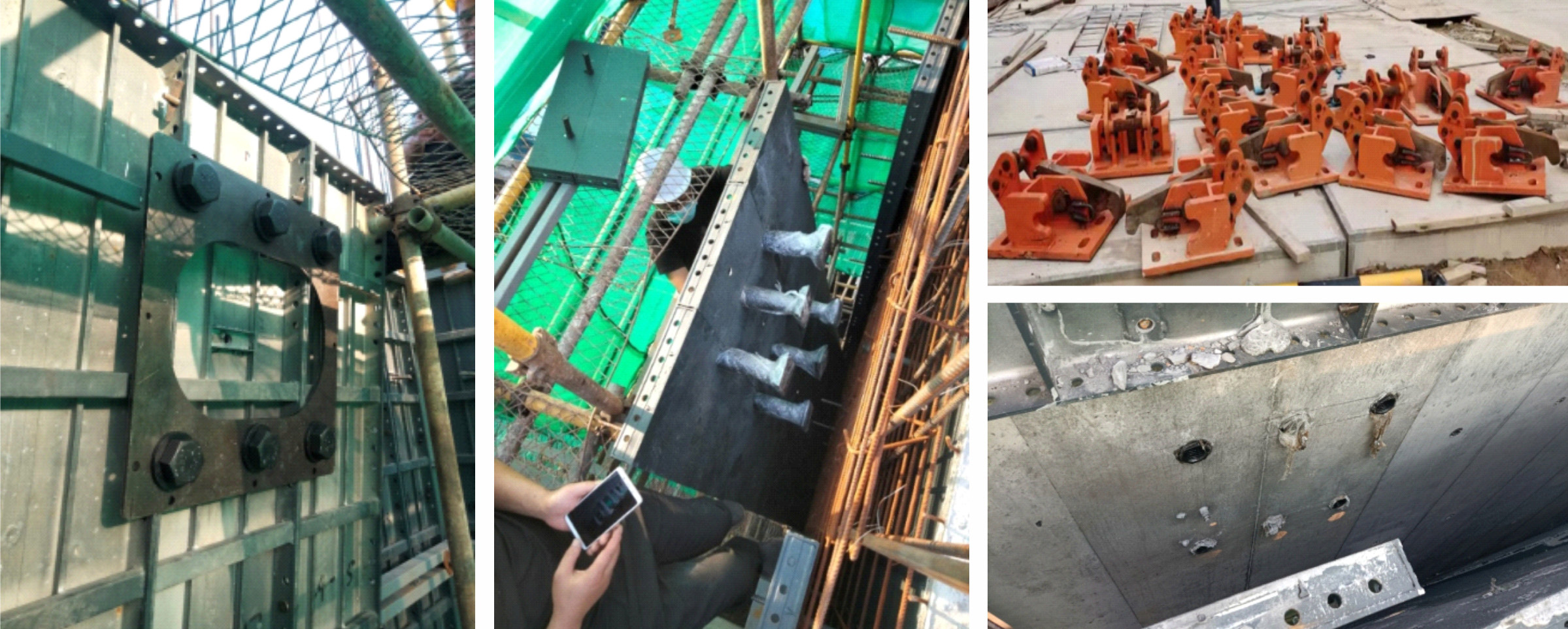

Installation of embedded parts for residential building machines

Installation of embedded parts for residential building machines